Streamline Your Process With Our Premier Y Strainers

High-quality Y strainer manufacturer in Singapore for diverse industrial applications

About Us

Expert Y Strainer Manufacturer in Singapore

Cadalan, a leading Y strainer manufacturer in Singapore, with 10+ years of expertise, is dedicated to supplying components with precision, innovation, and customer satisfaction. The dedication to excellence is evident in the great craftsmanship of our extensive selection of strainers, customized to suit various industries including manufacturing and processing water treatment, marine industry, HAVC systems, and chemical processing. At Cadalan, our main aim is to innovate using sustainable methods, striving to exceed expectations for durability and performance. We believe in delivering top-notch quality and ensuring customer satisfaction, which in turn fosters trust on a global scale. Our Product presence extends globally with a strong presence in the USA, UK, Australia, Saudi Arabia, Qatar, UAE, Africa, Thailand, Vietnam, New Zealand, Oman, and Indonesia.

Product Specifications

Y Strainer

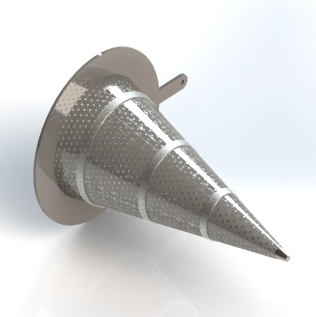

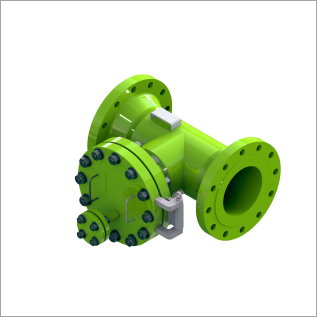

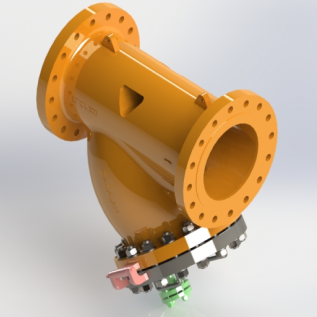

The Y strainer, with its unique Y-shaped design, is essential for keeping fluid systems clean by filtering out impurities and debris effectively. What sets it apart is its flexibility. It can be installed vertically or horizontally, depending on your preference. Crafted with precision and expertise, Cadalan provides Y strainers that meet strict quality standards up to 24 inches in size and classes from #150 to #10,000, offering a versatile solution for various applications.

Cadalan marks it as a high-quality Y strainer manufacturer in Singapore with careful material selection, and precision engineering, with exceptional efficiency. Each component of our Y strainers undergoes meticulous testing and inspection to ensure durability and efficiency. The materials used in their construction are carefully selected for their resilience and compatibility with different fluids, making our Y strainers a reliable choice for a wide range of applications.

- Sizes - 1 to 24 inches

- Types: Casting, Fabricated & Butt Welded

- Connection: Flanged & Butt Welded

- Classes : #150, #300, #400, #600, #900, #1500, #2500 upto #10,000

Fabricated Type Y Strainer

- Carbon Steel -ASTM A106 GR B/C, API 5L X65, A333 GR 6, ASTM A671

- Stainless Steel - ASTM A312 TP316 / 316L, ASTM A358 TP316 / 316L

- Duplex Stainless Steel - ASTM A928 S31803, ASTM A790 S31800

- Super Duplex Stainless Steel - ASTM A928 S32750 / 32760, ASTM A790 S32750/32760

- Nickel Aluminium Bronze Alloy - ASTM B148 C95800

- Monel -ASTM B165 K400/K500 (UNS N05400 / UNSN04400)

- Titanium grade 2 & 5 - ASTM B337 GR2 / GR5

Casting Type Y Strainer

- Carbon Steel - A216 WCB / WCC

- Low-Temperature Carbon Steel - LF2

- Stainless Steel - CF8 | CF8M | CF3 | CF3M

- Duplex Stainless Steel -A995 GR.4A

- Super Duplex Stainless Steel - A995 GR.5A

- Nickel Aluminium Bronze Alloy - ASTM B148 C95800

- Monel - K400 / K500

- Materials comply with NACE MR 01-75 NORSOK requirements

Our Dimension Chart for Y Strainer in Detail

Ensure precision with your selection by reviewing the dimensions of our Y strainer below

| SIZE | DIMENSIONS | WEIGHTS | |||||||||||||||||||

| A (END TO END) | B (HORIZONTAL) | C (VERTICAL) | D (FILTER REMOVAL) | ||||||||||||||||||

| CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | ||||||||||||

| INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | LBS | KGS | LBS | KGS |

| 2 | 50 | 10.43 | 265 | 10.55 | 268 | 5.04 | 128 | 5.04 | 128 | 5.94 | 151 | 6.30 | 160 | 10.83 | 275 | 11.81 | 300 | 30.86468 | 14 | 44.09 | 20 |

| 3 | 80 | 12.28 | 312 | 13.07 | 332 | 6.77 | 172 | 6.77 | 172 | 7.20 | 183 | 7.20 | 183 | 13.39 | 340 | 14.17 | 360 | 57.32012 | 26 | 79.37 | 36 |

| 4 | 100 | 14.33 | 364 | 15.04 | 382 | 8.27 | 210 | 8.27 | 210 | 8.23 | 209 | 8.90 | 226 | 16.14 | 410 | 16.34 | 415 | 83.77556 | 38 | 127.87 | 58 |

| 6 | 150 | 18.27 | 464 | 19.06 | 484 | 11.26 | 286 | 11.26 | 286 | 10.28 | 261 | 11.10 | 282 | 20.47 | 520 | 20.47 | 520 | 141.09568 | 64 | 249.12 | 113 |

| 8 | 200 | 22.05 | 560 | 22.76 | 578 | 14.02 | 356 | 14.02 | 356 | 12.28 | 312 | 13.19 | 335 | 24.41 | 620 | 25.00 | 635 | 231.4851 | 105 | 379.19 | 172 |

| 10 | 250 | 25.04 | 636 | 26.30 | 668 | 17.01 | 432 | 17.01 | 432 | 13.86 | 352 | 15.16 | 385 | 28.35 | 720 | 29.13 | 740 | 330.693 | 150 | 597.45 | 271 |

| 12 | 300 | 29.06 | 738 | 30.31 | 770 | 20.00 | 508 | 20.00 | 508 | 15.91 | 404 | 18.43 | 468 | 32.68 | 830 | 32.28 | 820 | 493.83488 | 224 | 873.03 | 396 |

| 14 | 350 | 31.97 | 812 | 33.23 | 844 | 21.97 | 558 | 21.97 | 558 | 17.48 | 444 | 18.86 | 479 | 35.83 | 910 | 32.68 | 830 | 650.3629 | 295 | 1179.47 | 535 |

| 16 | 400 | 34.02 | 864 | 35.51 | 902 | 24.02 | 610 | 24.02 | 610 | 18.58 | 472 | 20.16 | 512 | 38.58 | 980 | 38.98 | 990 | 837.7556 | 380 | 1521.19 | 690 |

| 18 | 450 | 38.03 | 966 | 39.53 | 1004 | 27.01 | 686 | 27.01 | 686 | 20.71 | 526 | 22.24 | 565 | 43.31 | 1100 | 43.90 | 1115 | 1042.78526 | 473 | 1940.07 | 880 |

| 20 | 500 | 41.42 | 1052 | 42.76 | 1086 | 30.00 | 762 | 30.00 | 762 | 22.52 | 572 | 24.02 | 610 | 47.24 | 1200 | 47.64 | 1210 | 1327.18124 | 602 | 2425.08 | 1100 |

| 24 | 600 | 46.06 | 1170 | 47.32 | 1202 | 34.02 | 864 | 34.02 | 864 | 25.04 | 636 | 26.54 | 674 | 53.82 | 1367 | 51.57 | 1310 | 1924.63326 | 873 | 3644.24 | 1653 |

Sizing the mesh filter for a Y strainer

In a Y strainer, the mesh size and micron rating are critical for filtration efficiency, with lower mesh sizes capturing larger particles and higher mesh sizes ideal for finer filtration. The micron size indicates the particle diameter the strainer can filter out, with smaller microns finer particles can be filtered.

Y strainers remove unwanted particles from steam, gas, or liquid using a wire mesh straining element, protecting equipment from pumps to steam traps. Some Y strainers feature “blow-off valves” for easier cleaning.

By carefully selecting the mesh and micron sizes based on the application’s requirements, Y strainers can effectively remove impurities from fluid streams, ensuring the integrity and quality of the process. As a prominent Y strainer manufacturer in Singapore, Cadalan enables you to achieve optimal filtration efficiency.

Dimension Chart

| Mesh Size | Microns | Inches |

|---|---|---|

| 3 | 6730 | 0.265 |

| 4 | 4760 | 0.187 |

| 5 | 4000 | 0.157 |

| 6 | 3360 | 0.132 |

| 7 | 2830 | 0.111 |

| 8 | 2380 | 0.0937 |

| 10 | 2000 | 0.0787 |

| 12 | 1680 | 0.0661 |

| 14 | 1410 | 0.0555 |

| 16 | 1190 | 0.0469 |

| 18 | 1000 | 0.0394 |

| 20 | 841 | 0.0331 |

| 25 | 707 | 0.028 |

| 30 | 595 | 0.0232 |

| 35 | 500 | 0.0197 |

| 40 | 400 | 0.0165 |

| 45 | 354 | 0.0138 |

| 50 | 297 | 0.0117 |

| 60 | 250 | 0.0098 |

| 70 | 210 | 0.0083 |

| 80 | 177 | 0.007 |

| 100 | 149 | 0.0059 |

| 120 | 125 | 0.0049 |

| 140 | 105 | 0.0041 |

| 170 | 88 | 0.0035 |

| 200 | 74 | 0.0029 |

| 230 | 63 | 0.0024 |

| 270 | 53 | 0.0021 |

| 325 | 44 | 0.0017 |

| 400 | 37 | 0.0015 |

Usages

Applications Of The Y Strainer

Why Choose

Why Choose Cadalan For Y Strainer Manufacturer in Singapore

Cadalan has emerged as a respected and authorized Y strainer manufacturer in Singapore, celebrated for its unwavering dedication to maintaining the most stringent quality standards, supported by more than a decade of industry expertise. Cadalan has a global presence, offering tailored solutions that meet diverse industrial needs. Our dedication to excellence has established them as the preferred choice for top-tier Y strainers among clients worldwide.

Decade of Expertise

Trust our decade-long expertise in designing reliable basket strainers that keep your systems running smoothly.

Global Reach

From New York to Tokyo, our Y strainers are trusted worldwide for their quality and performance.

Quality Assurance

Our Y strainers are built to last, ensuring your systems are protected from debris and contaminants.

100+ Happy Clients

Join our satisfied clients who rely on our Y strainers to maintain their industrial processes with ease.

Need an industrial solution? We've got your back!

Features And Benefits Of Y Strainer

The future of Y Strainers holds promising advancements and several benefits for fluid systems in various industries

Enhanced Efficiency:

Future Y Strainer designs are expected to focus on maximizing filtration efficiency, ensuring even finer particles are effectively captured. This contributes to the overall efficiency of fluid systems by maintaining cleaner pipelines and protecting downstream equipment.

Smart Integration:

Advancements in sensor technology and connectivity may lead to the development of smart Y Strainers. These innovations could enable real-time monitoring of filtration performance, allowing for predictive maintenance and proactive system management.

Material Innovations:

Ongoing research into materials science may result in using advanced materials for Y Strainer construction. This can lead to improved corrosion resistance, longer lifespan, and the ability to handle more extreme operating conditions.

Environmental Sustainability:

Future Y Strainer designs may incorporate eco-friendly materials and feature energy-efficient filtration processes. This aligns with the growing emphasis on sustainable practices in industries and contributes to environmental conservation.

Cost Savings:

The evolving Y Strainer technology is poised to improve cost-effectiveness by enhancing filtration efficiency, preventing downstream equipment damage, and reducing maintenance costs and downtime. Innovations in manufacturing processes may further drive economical production methods.

In conclusion, the future of Y Strainers holds exciting prospects with advancements in efficiency, smart integration, materials, environmental sustainability, and cost savings. Embracing these innovations can lead to more reliable and sustainable fluid systems across various industries.

How to Choose the Right Y Strainer to Handle Fluids

Struggling to choose the perfect Y strainer to handle the fluids efficiently? Reading further will help you find the perfect Y strainer to get your work done.

Understand Your Fluid:

Analyze the fluid type, including viscosity, temperature, and contaminants, to select a Y strainer with the appropriate mesh size and material for optimal compatibility.

Evaluate Flow Rate:

Determine your system’s flow rate to ensure the Y strainer can handle the expected volume without causing pressure drops or flow restrictions. Optimal performance relies on choosing the correct Y strainer size and configuration based on your flow requirements.

Consider Installation and Maintenance:

Assess the installation environment and accessibility for maintenance. Choose a Y strainer design that allows for easy installation, inspection, and cleaning to minimize downtime and ensure efficient operation over time.

Material Compatibility:

Select a Y strainer constructed from materials compatible with your fluid and operating conditions to prevent corrosion, erosion, or other forms of degradation. Consider factors like chemical compatibility, temperature resistance, and environmental conditions.

Quality and Standards:

Look for Y strainers that meet industry standards and certifications for quality and performance. Ensure the manufacturer has a reputation for producing reliable products and provides adequate support, including technical specifications and after-sales service, to meet your specific fluid handling needs.

We Work Globally

Our Clients

With a strong focus on durability, efficiency, and customer satisfaction,

we pride ourselves on delivering reliable filtration solutions trusted by clients across the globe.

___Testimonials

The Best Industry

The Best Industry

The Best Industry

Connect

Get Into Touch

Your Questions

Frequently Asked Questions

To clean a Y Strainer, isolate and depressurize the system, remove the cap to access the strainer element, inspect for debris, and clean or replace the element as needed. Thoroughly examine seals and housing for wear, reassemble the strainer, and reconnect to the system. Regularly schedule maintenance to ensure optimal performance and prevent potential issues in fluid filtration.

Y Strainers are commonly used in various industries for efficient fluid filtration. They play a vital role in applications such as chemical processing, water treatment, oil and gas, and manufacturing. In these sectors, Y Strainers effectively removes impurities, safeguarding equipment and ensuring the uninterrupted flow of fluids. Their versatility and reliability make them indispensable components in diverse industrial processes.

Typically, Y Strainers require maintenance every 3 to 6 months, but the frequency depends on the specific application and fluid conditions. Cleaning is straightforward: isolate the strainer, remove the cover, inspect and clean the mesh or replace it if necessary, and reassemble. Regular maintenance ensures optimal performance and prolongs the life of the Y Strainer in fluid systems.

The significance of pressure drop in a Y strainer lies in its impact on system efficiency. To minimize pressure drop for optimal performance, choose a Y strainer with a large area and suitable mesh size, and ensure regular cleaning or replacement of the element to maintain unobstructed fluid flow. Proper sizing, installation, and maintenance are crucial factors in reducing pressure drop and maximizing system efficiency.

Y Strainers come in standard sizes but can be customized for specific requirements, adapting to unique system specifications. This flexibility ensures suitability for diverse applications. Consult manufacturers for insights into the best sizing options based on specific fluid handling needs.

The sealing mechanism in a Y Strainer is crucial for maintaining a tight seal, preventing unfiltered fluid bypass, and optimizing filtration efficiency. A well-designed mechanism ensures effective impurity capture, safeguarding downstream equipment and maintaining fluid system integrity. Regular inspection and maintenance are essential for sustained, efficient filtration performance.

Specializing in tailored solutions, we offer custom designs for diverse industrial applications. Our expertise ensures precise adaptations to meet unique requirements, promoting optimal performance. Collaborating closely with clients, we create bespoke solutions that underscore our commitment to precision and versatility. Trust us for customized designs that enhance efficiency and reliability in your industrial processes.