Precise excellence in making individual components with remarkable standards

Maximize Efficiency With Our Unbeatable Tee Strainer

About Us

We are a top-notch Tee Strainer Manufacturer in Singapore

Cadalan, a leading Tee Strainer manufacturer in Singapore, with 10+ years of expertise, is dedicated to supplying components with precision, innovation, and customer satisfaction. The quality craftsmanship of our wide variety of strainers, customized for industries like manufacturing and processing, truly embodies our dedication to excellence in refineries and petrochemicals, food, and textile industries. At Cadalan, we constantly strive to push the envelope and set new standards for performance and durability. We place a high value on technological innovation and environmentally friendly practices. Our global trust stems from our relentless commitment to delivering top-notch products and prioritizing our customers’ needs above all else. Our Product presence extends globally with a strong presence in the USA, UK, Australia, Saudi Arabia, Qatar, UAE, Africa, Thailand, Vietnam, New Zealand, Oman, and Indonesia.

Product Specifications

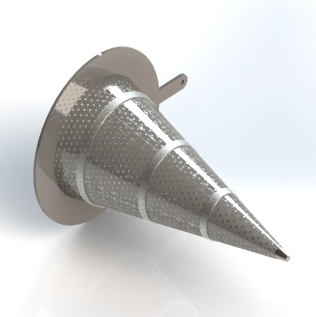

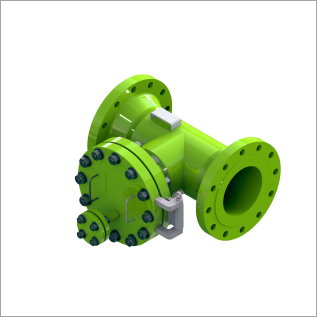

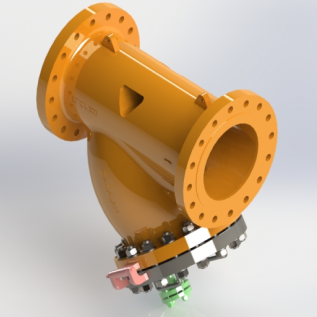

Tee Strainer

Tee strainers are essential components in piping systems, effectively filtering solid particles from flowing liquids. Their “T” shape allows easy installation in pipelines, where they safeguard equipment like pumps, valves, and meters from damage caused by contaminants. The tee strainer is designed with a straining element (such as a perforated screen or mesh) inside the horizontal section of the tee. Size varies from 1”- 48”.

Cadalan is a recognized top-tier Tee strainer manufacturer in Singapore, distinguished by meticulous material selection and precision engineering, resulting in outstanding industry standards from design to production. Our skilled technicians meticulously inspect each component, ensuring tee strainers are durable and high-performing. This dedication has earned us a global reputation for top-quality products trusted by engineers worldwide.

- Upto 24 inches

- Class: #150 upto #2500

Fabricated Type Tee Strainer

- Carbon Steel -A234 GR WPB/WPC, ASTM 420 Gr WPL6, ASTM A860 WPHY65

- Stainless Steel -ASTM A403 WP316/316L, ASTM A815 S31803/ S32750/S32760

- Duplex Stainless Steel - ASTM A815 S31803

- Super Duplex Stainless Steel -ASTM A815 S32750/S32760

- Nickel Aluminium Bronze Alloy - ASTM B148 C95800

- Monel - K400/K500 - ASTM B366 UNS N0400 / UNS N05500

- Titanium Grade 2 & 5 - ASTM B363 GR 2/ GR 5

Casting Type Tee Strainer

- Carbon Steel - A216 WCB / WCC

- Low-Temperature Carbon Steel - LF2

- Stainless Steel - CF8 | CF8M | CF3 | CF3M

- Duplex Stainless Steel - A995 GR.4A

- Super Duplex Stainless Steel - A995 GR.5A

- Nickel Aluminium Bronze Alloy - ASTM B148 C95800

- Monel - K400 / K500

Our Dimension Chart for Tee Strainer in Detail

Ensure precision with your selection by reviewing the dimensions of our Tee strainer below

| SIZE | DIMENSIONS | WEIGHTS | |||||||||||||||||||

| A (END TO END) | B (HORIZONTAL) | C (VERTICAL) | D (FILTER REMOVAL) | ||||||||||||||||||

| CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | ||||||||||||

| INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | LBS | KGS | LBS | KGS |

| 2 | 50 | 10.43 | 265 | 10.55 | 268 | 5.04 | 128 | 5.04 | 128 | 5.94 | 151 | 6.30 | 160 | 10.83 | 275 | 11.81 | 300 | 30.86468 | 14 | 44.09 | 20 |

| 3 | 80 | 12.28 | 312 | 13.07 | 332 | 6.77 | 172 | 6.77 | 172 | 7.20 | 183 | 7.20 | 183 | 13.39 | 340 | 14.17 | 360 | 57.32012 | 26 | 79.37 | 36 |

| 4 | 100 | 14.33 | 364 | 15.04 | 382 | 8.27 | 210 | 8.27 | 210 | 8.23 | 209 | 8.90 | 226 | 16.14 | 410 | 16.34 | 415 | 83.77556 | 38 | 127.87 | 58 |

| 6 | 150 | 18.27 | 464 | 19.06 | 484 | 11.26 | 286 | 11.26 | 286 | 10.28 | 261 | 11.10 | 282 | 20.47 | 520 | 20.47 | 520 | 141.09568 | 64 | 249.12 | 113 |

| 8 | 200 | 22.05 | 560 | 22.76 | 578 | 14.02 | 356 | 14.02 | 356 | 12.28 | 312 | 13.19 | 335 | 24.41 | 620 | 25.00 | 635 | 231.4851 | 105 | 379.19 | 172 |

| 10 | 250 | 25.04 | 636 | 26.30 | 668 | 17.01 | 432 | 17.01 | 432 | 13.86 | 352 | 15.16 | 385 | 28.35 | 720 | 29.13 | 740 | 330.693 | 150 | 597.45 | 271 |

| 12 | 300 | 29.06 | 738 | 30.31 | 770 | 20.00 | 508 | 20.00 | 508 | 15.91 | 404 | 18.43 | 468 | 32.68 | 830 | 32.28 | 820 | 493.83488 | 224 | 873.03 | 396 |

| 14 | 350 | 31.97 | 812 | 33.23 | 844 | 21.97 | 558 | 21.97 | 558 | 17.48 | 444 | 18.86 | 479 | 35.83 | 910 | 32.68 | 830 | 650.3629 | 295 | 1179.47 | 535 |

| 16 | 400 | 34.02 | 864 | 35.51 | 902 | 24.02 | 610 | 24.02 | 610 | 18.58 | 472 | 20.16 | 512 | 38.58 | 980 | 38.98 | 990 | 837.7556 | 380 | 1521.19 | 690 |

| 18 | 450 | 38.03 | 966 | 39.53 | 1004 | 27.01 | 686 | 27.01 | 686 | 20.71 | 526 | 22.24 | 565 | 43.31 | 1100 | 43.90 | 1115 | 1042.78526 | 473 | 1940.07 | 880 |

| 20 | 500 | 41.42 | 1052 | 42.76 | 1086 | 30.00 | 762 | 30.00 | 762 | 22.52 | 572 | 24.02 | 610 | 47.24 | 1200 | 47.64 | 1210 | 1327.18124 | 602 | 2425.08 | 1100 |

| 24 | 600 | 46.06 | 1170 | 47.32 | 1202 | 34.02 | 864 | 34.02 | 864 | 25.04 | 636 | 26.54 | 674 | 53.82 | 1367 | 51.57 | 1310 | 1924.63326 | 873 | 3644.24 | 1653 |

Sizing the mesh filter for a Tee strainer

A Tee strainer consists of a T-shaped body with a removable strainer basket and a cover for easy access. Cadalan manufactures them in a way that requires only simple installation in pipelines to remove debris and contaminants from liquids and gases.

The mesh size and micron rating are crucial for a T-strainer’s filtration efficiency. Mesh size indicates the number of openings per inch, while the micron rating specifies the particle size the strainer can capture.

Lower mesh sizes capture larger particles, higher mesh sizes are for finer filtration, and smaller micron sizes offer superior filtration. Careful selection of mesh and micron sizes allows T-strainers to efficiently remove impurities, ensuring process integrity.

What is Mesh Size:

- Unit of Measurement: Mesh size is typically expressed in terms of the number of openings per linear inch.

- Definition: Mesh size refers to the number of openings per linear inch in a strainer or filter. It is often used in woven wire mesh or perforated plate filters.

What is Micron Size:

- Unit of Measurement: Micron (µm) is a metric unit of length equal to one-millionth of a meter.

- Definition: Micron size refers to the diameter of a particle that can pass through an opening in a strainer or filter

Dimension Chart

| Mesh Size | Microns | Inches |

|---|---|---|

| 3 | 6730 | 0.265 |

| 4 | 4760 | 0.187 |

| 5 | 4000 | 0.157 |

| 6 | 3360 | 0.132 |

| 7 | 2830 | 0.111 |

| 8 | 2380 | 0.0937 |

| 10 | 2000 | 0.0787 |

| 12 | 1680 | 0.0661 |

| 14 | 1410 | 0.0555 |

| 16 | 1190 | 0.0469 |

| 18 | 1000 | 0.0394 |

| 20 | 841 | 0.0331 |

| 25 | 707 | 0.028 |

| 30 | 595 | 0.0232 |

| 35 | 500 | 0.0197 |

| 40 | 400 | 0.0165 |

| 45 | 354 | 0.0138 |

| 50 | 297 | 0.0117 |

| 60 | 250 | 0.0098 |

| 70 | 210 | 0.0083 |

| 80 | 177 | 0.007 |

| 100 | 149 | 0.0059 |

| 120 | 125 | 0.0049 |

| 140 | 105 | 0.0041 |

| 170 | 88 | 0.0035 |

| 200 | 74 | 0.0029 |

| 230 | 63 | 0.0024 |

| 270 | 53 | 0.0021 |

| 325 | 44 | 0.0017 |

| 400 | 37 | 0.0015 |

Usages

Applications Of The Tee Strainer

Why Choose Cadalan For Tee Strainer in Singapore

Cadalan - The Best Tee Strainer Manufacturer in Singapore

Cadalan is a renowned tee strainer manufacturer in Singapore, renowned for its steadfast commitment to quality assurance, supported by over a decade of industry expertise. With a global footprint, Cadalan caters to clients worldwide, delivering dependable and effective solutions for a wide range of industrial needs. The company’s unwavering dedication to excellence has established it as the preferred choice for those in search of top-notch tee strainers.

Decade of Expertise

Rely on our ten years of expertise in crafting dependable tee strainers that ensure the smooth operation of your systems.

Global Reach

From New York to Tokyo, our Tee strainers are trusted worldwide for their quality and performance.

Quality Assurance

Our tee strainers are built to last, guaranteeing the protection of your systems from debris and contaminants.

100+ Happy Clients

Join our roster of satisfied clients who depend on our Tee strainers to maintain their industrial processes effortlessly.

Looking for industrial filtration? We've got you covered with our ultimate Tee strainers!

How does a Tee Strainer work?

A Tee strainer is a type of filtration device used in pipelines to remove solid particles or debris from a flowing fluid, such as water or gas. It typically consists of a T-shaped fitting with a strainer element inside. Here’s a brief overview of how a tee strainer works:

Installation:

Installed horizontally in a pipeline, the tee strainer’s T-shaped design diverts fluid through its perpendicular leg. This strategic placement facilitates efficient filtration.

Fluid Flow:

Fluid traversing the pipeline enters the tee strainer. The T-shape enables simultaneous flow through the main pipeline and diversion through the strainer section.

Straining Process:

Diverted fluid encounters a mesh or perforated screen, capturing solid particles. This straining process effectively removes debris and impurities from the fluid.

Cleaned Fluid:

The now-filtered fluid reintegrates with the main pipeline, boasting reduced contaminant levels for smoother operation.

Maintenance:

Regular inspection and cleaning, involving shutdown, strainer element removal, and replacement, are essential to ensure sustained effectiveness and prevent system issues caused by accumulated debris.

Tee strainers are commonly used in systems where the removal of particulate matter is essential to protect downstream equipment, such as pumps, valves, and meters, from damage or clogging. They find applications in various industries, including water treatment, oil and gas, chemical processing, and more. The effectiveness of a Tee strainer depends on factors like the mesh size of the strainer element and the flow rate through the system.

Tee Strainer vs. Y Strainer — What's Your Pick?

Tee Strainer:

- Design: Resembles the letter “Tee” and is installed in the pipeline with the strainer element located in the perpendicular leg of the Tee.

- Fluid Flow: Fluid flows through the main pipeline, and a portion is diverted through the strainer section.

- Application: Effective for applications where space is limited and a compact design is necessary.

Y-Strainer:

- Design: Resembles the letter “Y” and is installed in the pipeline with the strainer element located in the angled leg of the Y.

- Fluid Flow: Similar to the Tee Strainer, fluid flows through the main pipeline, but a portion is diverted through the strainer section in a Y-shaped configuration.

- Application: Suitable for applications with a higher flow rate and where a larger straining area is needed.

Considerations:

- Space and Flow Rate: Tee Strainers are more compact, making them suitable for installations with limited space, while Y-strainers may offer a larger straining area and can handle higher flow rates.

- Installation: Tee Strainers may be easier to install in tight spaces due to their compact design, while Y-strainers might offer advantages in applications with specific flow requirements.

- Maintenance: Both types require periodic inspection and cleaning, involving shutting down the system to remove and clean the strainer element.

The choice between a Tee Strainer and a Y-Strainer still depends on specific application requirements, space constraints, and desired flow characteristics.

We Work Globally

Our Clients

With a strong focus on durability, efficiency, and customer satisfaction,

we pride ourselves on delivering reliable filtration solutions trusted by clients across the globe.

___Testimonials

The Best Industry

The Best Industry

The Best Industry

Connect

Get Into Touch

Your Questions

Frequently Asked Questions

Tee strainers are typically used in various industrial applications where it’s essential to remove solid particles or debris from a fluid flowing through a pipeline. Some common areas of use are the chemical, oil, and gas industries, power plants, and marine applications.

To install a Tee Strainer in a pipeline, cut and prepare the pipeline, position the Tee Strainer with the strainer element in the perpendicular leg, secure connections tightly, perform system checks for leaks, and gradually start the system. Regular maintenance ensures continued effectiveness in removing debris and maintaining fluid system integrity.

A Tee Strainer should be inspected and maintained regularly, typically at least once every three to six months, depending on the application and the level of contaminants present. This ensures optimal performance, prevents clogging, and extends the lifespan of the strainer in fluid systems

Yes, Tee Strainers are versatile and can be used in both liquid and gas applications. They effectively remove solid particles and debris from fluids, ensuring the protection of downstream equipment. Whether in water systems, chemical processing, or gas pipelines, Tee Strainers play a crucial role in maintaining system integrity.

Tee Strainers offer advantages in piping systems by efficiently removing solid particles, ensuring downstream equipment protection. Their compact design suits various applications, and customization options cater to specific needs. Easy maintenance and improved efficiency make Tee Strainers essential for safeguarding equipment and optimizing fluid flow in diverse industries.

Tee Strainers find common applications across diverse industries such as water treatment, chemical processing, oil and gas, power generation, HVAC systems, food and beverage, marine, mining, and pharmaceuticals. They effectively remove solid particles, safeguarding equipment and ensuring the integrity of fluid systems in various industrial processes.

Determine the right Tee Strainer by considering factors such as fluid type, flow rate, particle size, and system specifications. Consult with the manufacturer for guidance, ensuring the chosen strainer meets the specific requirements of your application, optimizing efficiency, and providing reliable protection to downstream equipment.

Cadalan leads as one of the best Tee Strainer manufacturer in Singapore due to their commitment to quality, durability, and industry compliance. With a solid reputation, Cadalan offers customized solutions, efficient customer support, and competitive pricing. Trust Cadalan for reliable Tee Strainers that meet stringent standards and provide optimal performance in diverse applications.