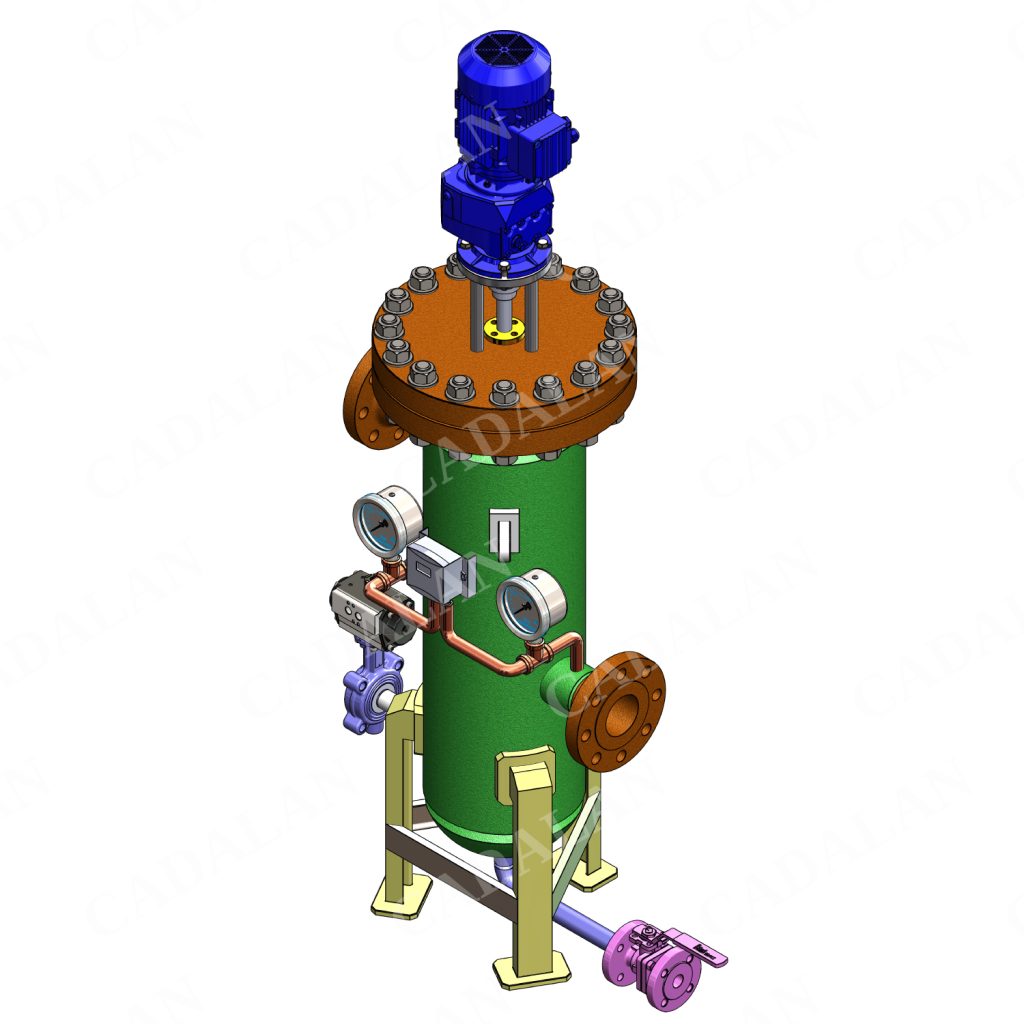

Self Cleaning Basket Strainers

Self Cleaning Basket Strainers

Self-Cleaning Strainers are a motorised strainer that is used to continually remove contaminants and debris from an industrial pipe system. The flow of liquid enters the strainer at the bottom and works its way upwards through the strainer and then out. Any unwanted debris is caught inside the strainer and pushed to the bottom. When the differential pressure reaches a set point the flush valve at the bottom opens and removes the contaminants.

- Size: Depending upon the customer requirements

- Types: Fabricated and Casting

- Connection: Flanged & Butt Welded

Construction Material (Fabricated Type)

- Carbon Steel – ASTM A106 GR B/C, API 5L X65, A333 GR 6, ASTM A67

- Stainless Steel – ASTM A312 TP316/316L, ASTM A358 TP316/316L

- Duplex Stainless Steel – ASTM A928 S31803, ASTM A790 S31803

- Super Duplex Stainless Steel – ASTM A928 S32750/32760, ASTM A790 S32750/3276º

- Nickel Aluminium Bronze Alloy – ASTM B148 C9580º

- MONEL – ASTM B165 K400/k500 ( UNS N05400 /UNS N04400)

- Titanium grade 2 & 5 – ASTM B337 GR 2 / GR 5