Achieve Superior Filtration with Precision and Quality

Experience Unmatched Filtration Quality with Cadalan’s Duplex Basket Strainers

About Us

Best Duplex Basket Strainer Supplier in UAE

Welcome to Cadalan, the leading duplex basket strainer supplier in UAE. With over ten years of experience, we specialize in delivering precision, creativity, and customer contentment. Our focus on excellence is reflected in our wide range of strainers designed for various industries, including manufacturing, processing plants, refineries, and oil and gas companies. We prioritize technological advancement and sustainable methods to establish new benchmarks in durability and performance. Our commitment to quality assurance and customer-centric approach has garnered international trust, leading to a strong presence in countries such as the USA, UK, Australia, Saudi Arabia, Qatar, UAE, Africa, Thailand, Vietnam, New Zealand, Oman, and Indonesia.

Product Specifications

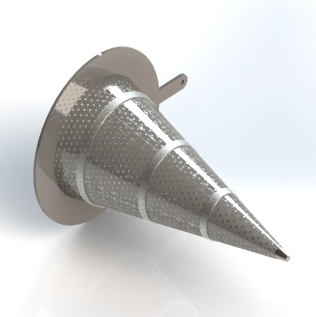

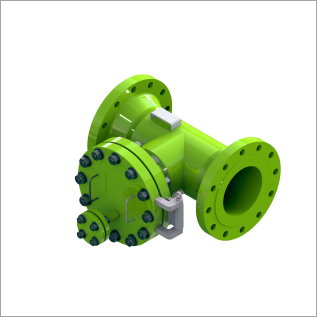

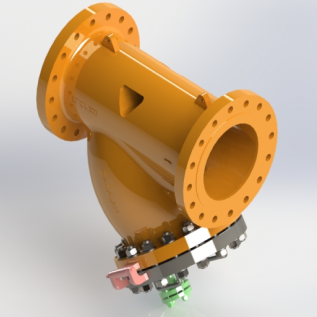

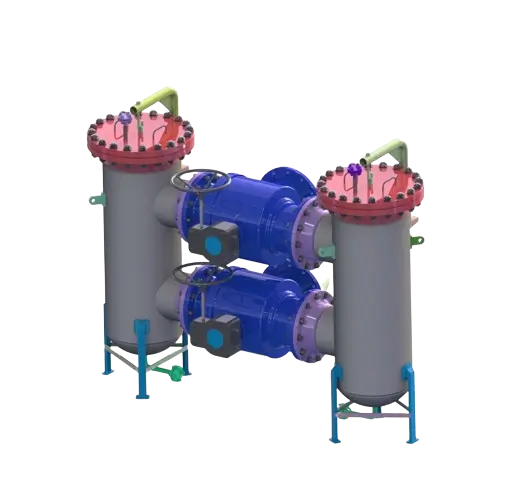

Duplex Basket Strainer

Duplex basket strainers offer unique design and functionality, enhancing filtration and operational excellence. Featuring two chambers, they ensure uninterrupted filtration during maintenance, unlike single-basket strainers. These devices remove particles from flowing fluids in pipelines, with sizes up to 24 inches, and classes from #150 to #2500 at Cadalan.

Rigorous quality control measures throughout production maintain high standards, including pressure resistance and filtration efficiency testing. This ensures efficient filtration, effortlessly removing contaminants from fluid streams.

- Upto 24 inches

- Class: #150 upto #2500

Fabricated Type Duplex Basket Strainer

- Carbon Steel - ASTM A106 GR B/C , API 5L X65, A333 GR 6 , ASTM A671

- Stainless Steel - ASTM A312 TP316/316L , ASTM A35t TP316/316L

- Duplex Stainless Steel - ASTM A928 S31803 , ASTM A790 S31803

- Super Duplex Stainless Steel - ASTM A928 S32750/32760 , ASTM A790 S32750/32760

- Nickel Aluminium Bronze Alloy - ASTM B14t C95800

- Monel - ASTM B165 K400/k500 ( UNS N05400 /UNS N04400 )

Casting Type Duplex Basket Strainer

- Carbon Steel - A216 WCB/ CFt8/CF8M - ASTM A106 B

- Low-Temperature Carbon Steel - A352 GR.LCC/CF3M

- Stainless Steel - SS316/ SS304

- Duplex Stainless Steel - A995 GR.4A / A995 GR.5A

- Nickel Aluminium Bronze Alloy - ASTM B14t C95t00/ UNSNO662

- Monel - UNSN04400 / UNSNO5500

- Inconel - UNS NO6625 & Titanium

Dimension Chart for Duplex Basket Strainer

Check out the dimensions of our duplex basket strainers for accurate size details.

| SIZE | DIMENSIONS | WEIGHTS | |||||||||||||||||||

| A (END TO END) | B (HORIZONTAL) | C (VERTICAL) | D (FILTER REMOVAL) | ||||||||||||||||||

| CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | ||||||||||||

| INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | LBS | KGS | LBS | KGS |

| 2 | 50 | 10.43 | 265 | 10.55 | 268 | 5.04 | 128 | 5.04 | 128 | 5.94 | 151 | 6.30 | 160 | 10.83 | 275 | 11.81 | 300 | 30.86468 | 14 | 44.09 | 20 |

| 3 | 80 | 12.28 | 312 | 13.07 | 332 | 6.77 | 172 | 6.77 | 172 | 7.20 | 183 | 7.20 | 183 | 13.39 | 340 | 14.17 | 360 | 57.32012 | 26 | 79.37 | 36 |

| 4 | 100 | 14.33 | 364 | 15.04 | 382 | 8.27 | 210 | 8.27 | 210 | 8.23 | 209 | 8.90 | 226 | 16.14 | 410 | 16.34 | 415 | 83.77556 | 38 | 127.87 | 58 |

| 6 | 150 | 18.27 | 464 | 19.06 | 484 | 11.26 | 286 | 11.26 | 286 | 10.28 | 261 | 11.10 | 282 | 20.47 | 520 | 20.47 | 520 | 141.09568 | 64 | 249.12 | 113 |

| 8 | 200 | 22.05 | 560 | 22.76 | 578 | 14.02 | 356 | 14.02 | 356 | 12.28 | 312 | 13.19 | 335 | 24.41 | 620 | 25.00 | 635 | 231.4851 | 105 | 379.19 | 172 |

| 10 | 250 | 25.04 | 636 | 26.30 | 668 | 17.01 | 432 | 17.01 | 432 | 13.86 | 352 | 15.16 | 385 | 28.35 | 720 | 29.13 | 740 | 330.693 | 150 | 597.45 | 271 |

| 12 | 300 | 29.06 | 738 | 30.31 | 770 | 20.00 | 508 | 20.00 | 508 | 15.91 | 404 | 18.43 | 468 | 32.68 | 830 | 32.28 | 820 | 493.83488 | 224 | 873.03 | 396 |

| 14 | 350 | 31.97 | 812 | 33.23 | 844 | 21.97 | 558 | 21.97 | 558 | 17.48 | 444 | 18.86 | 479 | 35.83 | 910 | 32.68 | 830 | 650.3629 | 295 | 1179.47 | 535 |

| 16 | 400 | 34.02 | 864 | 35.51 | 902 | 24.02 | 610 | 24.02 | 610 | 18.58 | 472 | 20.16 | 512 | 38.58 | 980 | 38.98 | 990 | 837.7556 | 380 | 1521.19 | 690 |

| 18 | 450 | 38.03 | 966 | 39.53 | 1004 | 27.01 | 686 | 27.01 | 686 | 20.71 | 526 | 22.24 | 565 | 43.31 | 1100 | 43.90 | 1115 | 1042.78526 | 473 | 1940.07 | 880 |

| 20 | 500 | 41.42 | 1052 | 42.76 | 1086 | 30.00 | 762 | 30.00 | 762 | 22.52 | 572 | 24.02 | 610 | 47.24 | 1200 | 47.64 | 1210 | 1327.18124 | 602 | 2425.08 | 1100 |

| 24 | 600 | 46.06 | 1170 | 47.32 | 1202 | 34.02 | 864 | 34.02 | 864 | 25.04 | 636 | 26.54 | 674 | 53.82 | 1367 | 51.57 | 1310 | 1924.63326 | 873 | 3644.24 | 1653 |

Sizing the Mesh Filter for a Duplex Basket Strainer

The effectiveness of filtration in a duplex basket strainer depends significantly on the mesh and micron sizes. Mesh size denotes the number of openings per inch in the strainer screen, while micron size measures the particle size the strainer can trap.

Lower mesh sizes have larger openings, ideal for capturing bigger particles, whereas higher mesh sizes have smaller openings, suited for finer filtration. Micron size indicates the diameter of particles the strainer can filter, with smaller micron sizes offering finer filtration capabilities.

Choosing the right mesh and micron sizes based on the application’s needs allows duplex basket strainers to efficiently remove impurities from fluid streams, ensuring the integrity and quality of the process.

What is Mesh Size?

- Mesh size is usually indicated by the number of openings per linear inch and refers to the spacing of these openings in a strainer or filter, commonly seen in woven wire mesh or perforated plate filters.

What is Micron Size?

- Micron (µm) is a metric unit of length equal to one-millionth of a meter. Micron size indicates the diameter of a particle that can pass through an opening in a strainer or filter.

Dimension Chart

| Mesh Size | Microns | Inches |

|---|---|---|

| 3 | 6730 | 0.265 |

| 4 | 4760 | 0.187 |

| 5 | 4000 | 0.157 |

| 6 | 3360 | 0.132 |

| 7 | 2830 | 0.111 |

| 8 | 2380 | 0.0937 |

| 10 | 2000 | 0.0787 |

| 12 | 1680 | 0.0661 |

| 14 | 1410 | 0.0555 |

| 16 | 1190 | 0.0469 |

| 18 | 1000 | 0.0394 |

| 20 | 841 | 0.0331 |

| 25 | 707 | 0.028 |

| 30 | 595 | 0.0232 |

| 35 | 500 | 0.0197 |

| 40 | 400 | 0.0165 |

| 45 | 354 | 0.0138 |

| 50 | 297 | 0.0117 |

| 60 | 250 | 0.0098 |

| 70 | 210 | 0.0083 |

| 80 | 177 | 0.007 |

| 100 | 149 | 0.0059 |

| 120 | 125 | 0.0049 |

| 140 | 105 | 0.0041 |

| 170 | 88 | 0.0035 |

| 200 | 74 | 0.0029 |

| 230 | 63 | 0.0024 |

| 270 | 53 | 0.0021 |

| 325 | 44 | 0.0017 |

| 400 | 37 | 0.0015 |

Usages

Applications of the Duplex Basket Strainer

Why Choose Cadalan for Duplex Basket Strainer Supplier in UAE

Cadalan - The Best Duplex Basket Strainer Manufacturer in the UAE

Cadalan is a well-established and trusted leader in the manufacturing of duplex basket strainers, with a strong focus on ensuring top-notch quality assurance. With over a decade of valuable industry experience, our global presence allows us to cater to clients across the world. We offer dependable solutions customized to a wide variety of industrial applications. Our unwavering commitment to excellence has helped us build a great reputation in the market, positioning us as the preferred choice for a high-quality duplex basket strainer supplier in UAE among top-tier clients. When you choose Cadalan, you can trust that you’re selecting a reliable partner dedicated to providing superior products and services for your industrial needs.

Expertise Over Ten Years

Rely on our extensive ten-year experience in crafting dependable basket strainers that ensure the smooth operation of your systems.

Worldwide Presence

Whether in New York or Tokyo, our basket strainers are globally recognized for their excellence and efficiency.

Ensured Quality

Our basket strainers are constructed for longevity, guaranteeing that your systems remain safeguarded against debris and impurities.

Satisfied Customers

Become a part of our happy clientele who trust our basket strainers to effortlessly maintain their industrial operations.

Need an industrial solution? We've got your back!

Features and Benefits of the Duplex Basket Strainer

Cadalan’s duplex basket strainers are designed to keep factories running smoothly. They have two parts that let them work without stopping, even when one part needs maintenance. These strainers are easy to clean or fix because their baskets can be removed without shutting down the whole system. They come in different materials to suit different needs, making them reliable and effective at filtering out dirt and debris.

Duplex Design:

The duplex design of the basket strainer includes two chambers. This allows for continuous operation even when maintenance is being performed on one chamber. It ensures that one chamber can remain in operation while the other is being serviced, minimizing system downtime.

Removable Basket:

The basket in the strainer is removable, which simplifies maintenance. This feature allows the basket to be easily taken out for cleaning or replacement without needing to shut down the entire system. It saves time and effort in maintenance procedures.

Material Options:

The basket strainer offers versatility in construction materials. This means it can be constructed using different materials to suit specific application requirements. The ability to choose from a range of materials ensures that the strainer can withstand the demands of different environments and fluids.

Benefits:

Continuous Operation:

The duplex design and removable basket feature contribute to enhancing overall system reliability. The ability to maintain continuous operation, even during maintenance, ensures that the system can operate smoothly and consistently.

Reduced Downtime:

The removable basket design significantly reduces maintenance-related downtime. Since the basket can be easily removed for cleaning or replacement, there is no need to shut down the entire system. This reduces downtime, leading to increased productivity and cost savings.

Effective Filtration:

The basket strainer provides effective filtration, capturing a diverse range of particles and contaminants. This helps to protect downstream equipment and maintain system efficiency by ensuring that unwanted particles are removed from the fluid stream.

How to Choose the Right Duplex Basket Strainer

When selecting the right duplex basket strainer, several key factors should be considered:

Flow and Filtration Requirements:

Determine the required flow rate and the size of particles that need to be filtered. This will help you choose a strainer with the appropriate capacity and filtration efficiency.

Material Compatibility:

Assess the compatibility of the strainer’s construction materials with the fluid being processed. Ensure that the materials can withstand the chemical properties of the fluid to avoid corrosion or degradation.

Operating Conditions:

Consider the operating temperature and pressure of your system. Choose a strainer that is designed to handle these conditions to ensure reliable performance and longevity.

Ease of Maintenance:

Evaluate the design of the strainer to ensure that it is easy to maintain. Look for features such as removable baskets or quick-opening closures that simplify cleaning and maintenance procedures.

Compliance and Reputation:

Verify that the strainer complies with industry standards and regulations. Additionally, consider the manufacturer’s reputation for quality and reliability to ensure you are purchasing a dependable product.

By carefully considering these factors, you can choose a duplex basket strainer that meets your specific requirements and ensures efficient and reliable operation in your industrial application.

We Work Globally

Our Clients

With a keen emphasis on long-lasting quality, effectiveness, and ensuring customer contentment, we take pride in providing dependable filtration solutions that are trusted by customers worldwide.

___Testimonials

The Best Industry

The Best Industry

The Best Industry

Connect

Get in Touch

Your Questions

Frequently Asked Questions

To keep your duplex basket strainer in top condition, follow these steps: first, turn off the system. Then, remove the cover and take out the basket. Inspect and clean the basket thoroughly, and also clean the housing before putting everything back together.

To install a duplex basket strainer, align it with the pipeline and secure it with bolts. Connect the pipes, then open the valves and follow the manufacturer’s instructions for starting the system.

A duplex basket strainer is designed with two chambers, allowing for continuous operation during maintenance, which ensures a steady flow. In comparison, a simplex basket strainer has just one chamber and requires the system to be shut down for cleaning or maintenance. Using a duplex strainer can improve efficiency and reduce downtime in fluid filtration systems.

A duplex basket strainer works by utilizing two chambers, each with its own basket. This setup enables the strainer to maintain continuous fluid flow during maintenance by switching between the chambers, ensuring filtration is uninterrupted in industrial settings.

Yes, duplex basket strainers can handle corrosive environments by using materials like stainless steel or alloys that resist corrosion, ensuring they remain durable and reliable even in challenging industrial conditions.

Yes, duplex basket strainers are built to handle high-pressure applications. They are made with strong materials and sturdy construction to withstand the elevated pressures commonly found in industrial processes, ensuring efficient filtration without any compromise.

Duplex basket strainers are often made from materials such as stainless steel, carbon steel, alloys, and special coatings. The choice of material depends on factors like corrosion resistance, fluid compatibility, and specific application requirements in various industries.

If you have any questions or need assistance with Cadalan duplex basket strainers, you can reach our customer support team by calling our hotline at [provide phone number] or email us at [provide email address]. Our team is dedicated to addressing your concerns promptly.

The average lifespan of a duplex basket strainer can vary depending on factors like usage, maintenance practices, and operating conditions. With regular maintenance and following guidelines, duplex basket strainers can offer long-term reliable and efficient filtration.

Yes, Cadalan has the capability to efficiently manage large orders of duplex basket strainers. We ensure timely production and maintain high-quality standards to meet the demands of large-scale industrial applications which makes us the leading duplex basket strainer supplier in UAE.