Crafting Superiority Through Precision in Every Component

Refine Your Filtration Technique with Our High-Quality Basket Strainers

About Us

Leading Basket Strainer Manufacturer in Singapore

Cadalan, a trusted basket strainer manufacturer in Singapore, with 10+ years of expertise, is dedicated to supplying components with precision, innovation, and customer satisfaction. Our commitment to excellence is reflected in the quality craftsmanship of our diverse strainer range, tailored for industries such as manufacturing and processing plants, refineries, oil, and gas companies. At Cadalan, we prioritize technological innovation and sustainable practices, always pushing the boundaries to set new standards in durability and performance. Moreover, our unwavering dedication to quality assurance, coupled with a customer-focused approach, has earned us global trust. Our Product presence extends further globally, with a strong presence in the USA, UK, Australia, Saudi Arabia, Qatar, UAE, Africa, Thailand, Vietnam, New Zealand, Oman, and Indonesia.

Product Specifications

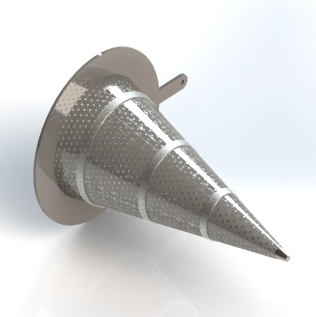

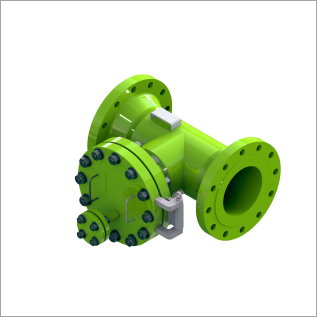

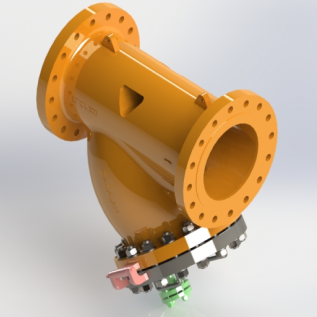

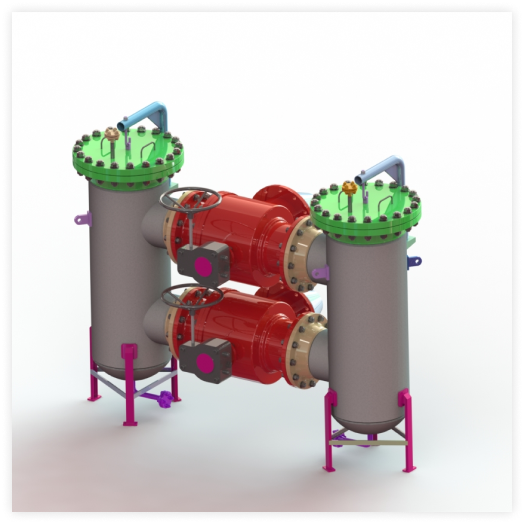

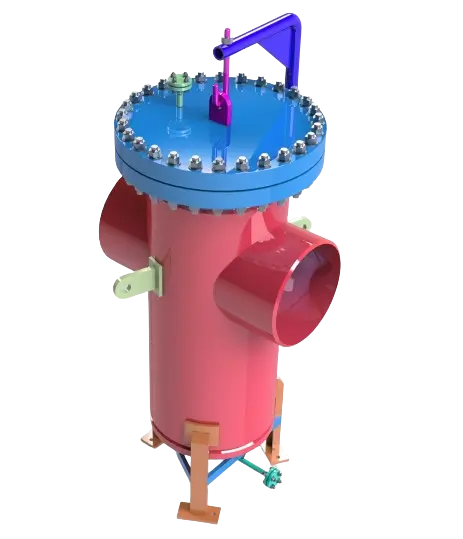

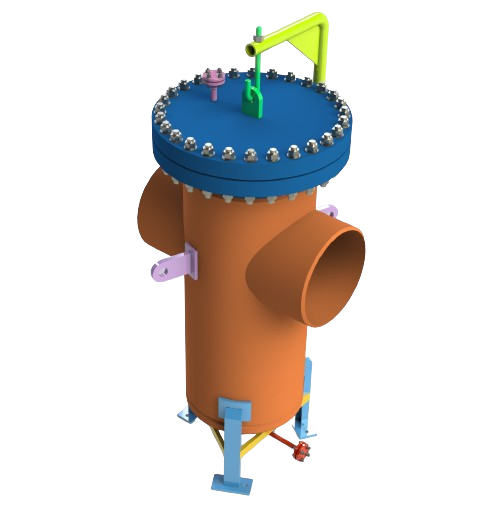

Basket Strainer

A Basket Strainer is vital for cleaning pipelines, and swiftly removing unwanted particles from liquid flows. Installed horizontally for high flow capacity. In addition, its simple yet effective design ensures smooth operations across industries. Placed before equipment like pumps and valves, it prevents harmful debris from causing damage downstream. At Cadalan, we offer duplex basket strainers in sizes up to 24 inches and classes from #150 to #10,000.

At Cadalan, we efficiently manufacture quality basket strainers through precision engineering and careful material selection, making us the leading basket strainer manufacturer in Singapore. Skilled technicians use advanced techniques to craft each component precisely. Moreover, rigorous quality control ensures our basket strainers meet high standards for durability and efficiency.

- Sizes - 1 to 24 inches

- Types: Casting, Fabricated & Butt Welded

- Connection: Flanged & Butt Welded

- Classes : #150, #300, #400, #600, #900, #1500, #2500 upto #10,000

Fabricated Type Basket Strainer

- Carbon Steel - ASTM A106 GR B/C, API 5L X65, A333 GR 6, ASTM A671

- Stainless Steel - ASTM A312 TP316 / 316L, ASTM A358 TP316 / 316L

- Duplex Stainless Steel - ASTM A928 S31803, ASTM A790 S31800

- Super Duplex Stainless Steel - ASTM A928 S32750 / 32760, ASTM A790 S32750/32760

- Nickel Aluminium Bronze Alloy - ASTM B148 C95800

- Monel - ASTM B165 K400/K500 (UNS N05400 / UNSN04400)

- Titanium grade 2 & 5 - ASTM B337 GR2 / GR5

Casting Type Basket Strainer

- Carbon Steel - A216 WCB / WCC

- Low - LF2

- Stainless Steel - CF8 | CF8M | CF3 | CF3M

- Duplex Stainless Steel - A995 GR.5A

- Super Duplex Stainless Steel - A995 GR.5A

- Nickel Aluminium Bronze Alloy - ASTM B148 C95800

- Monel - K400 / K500

- Titanium Grade 2 & 5 - ASTM B337 GR 2 / GR 5

- Materials comply with NACE MR 01-75 NORSOK requirements

Our Dimension Chart of Basket Strainer in Detail

Ensure precision with your selection by reviewing the dimensions of our basket strainers below

| SIZE | DIMENSIONS | WEIGHTS | |||||||||||||||||||

| A (END TO END) | B (HORIZONTAL) | C (VERTICAL) | D (FILTER REMOVAL) | ||||||||||||||||||

| CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | ||||||||||||

| INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | LBS | KGS | LBS | KGS |

| 2 | 50 | 10.43 | 265 | 10.55 | 268 | 5.04 | 128 | 5.04 | 128 | 5.94 | 151 | 6.30 | 160 | 10.83 | 275 | 11.81 | 300 | 30.86468 | 14 | 44.09 | 20 |

| 3 | 80 | 12.28 | 312 | 13.07 | 332 | 6.77 | 172 | 6.77 | 172 | 7.20 | 183 | 7.20 | 183 | 13.39 | 340 | 14.17 | 360 | 57.32012 | 26 | 79.37 | 36 |

| 4 | 100 | 14.33 | 364 | 15.04 | 382 | 8.27 | 210 | 8.27 | 210 | 8.23 | 209 | 8.90 | 226 | 16.14 | 410 | 16.34 | 415 | 83.77556 | 38 | 127.87 | 58 |

| 6 | 150 | 18.27 | 464 | 19.06 | 484 | 11.26 | 286 | 11.26 | 286 | 10.28 | 261 | 11.10 | 282 | 20.47 | 520 | 20.47 | 520 | 141.09568 | 64 | 249.12 | 113 |

| 8 | 200 | 22.05 | 560 | 22.76 | 578 | 14.02 | 356 | 14.02 | 356 | 12.28 | 312 | 13.19 | 335 | 24.41 | 620 | 25.00 | 635 | 231.4851 | 105 | 379.19 | 172 |

| 10 | 250 | 25.04 | 636 | 26.30 | 668 | 17.01 | 432 | 17.01 | 432 | 13.86 | 352 | 15.16 | 385 | 28.35 | 720 | 29.13 | 740 | 330.693 | 150 | 597.45 | 271 |

| 12 | 300 | 29.06 | 738 | 30.31 | 770 | 20.00 | 508 | 20.00 | 508 | 15.91 | 404 | 18.43 | 468 | 32.68 | 830 | 32.28 | 820 | 493.83488 | 224 | 873.03 | 396 |

| 14 | 350 | 31.97 | 812 | 33.23 | 844 | 21.97 | 558 | 21.97 | 558 | 17.48 | 444 | 18.86 | 479 | 35.83 | 910 | 32.68 | 830 | 650.3629 | 295 | 1179.47 | 535 |

| 16 | 400 | 34.02 | 864 | 35.51 | 902 | 24.02 | 610 | 24.02 | 610 | 18.58 | 472 | 20.16 | 512 | 38.58 | 980 | 38.98 | 990 | 837.7556 | 380 | 1521.19 | 690 |

| 18 | 450 | 38.03 | 966 | 39.53 | 1004 | 27.01 | 686 | 27.01 | 686 | 20.71 | 526 | 22.24 | 565 | 43.31 | 1100 | 43.90 | 1115 | 1042.78526 | 473 | 1940.07 | 880 |

| 20 | 500 | 41.42 | 1052 | 42.76 | 1086 | 30.00 | 762 | 30.00 | 762 | 22.52 | 572 | 24.02 | 610 | 47.24 | 1200 | 47.64 | 1210 | 1327.18124 | 602 | 2425.08 | 1100 |

| 24 | 600 | 46.06 | 1170 | 47.32 | 1202 | 34.02 | 864 | 34.02 | 864 | 25.04 | 636 | 26.54 | 674 | 53.82 | 1367 | 51.57 | 1310 | 1924.63326 | 873 | 3644.24 | 1653 |

Sizing the mesh filter for a Basket strainer

As a prominent basket strainer manufacturer in Singapore, we understand the pivotal role of mesh and micron dimensions in achieving optimal filtration efficiency. The mesh size denotes the number of openings per inch in the strainer screen, while the micron size specifies the particles’ dimensions that the strainer can effectively capture.

Each strainer features a mesh-lined basket to collect debris efficiently. Mesh size should suit the job, as overly small openings can lead to clogs, while larger ones may allow debris to pass through. Opt for a mesh slightly smaller than the smallest particle to be filtered.

Mesh size is measured by openings per inch, with higher numbers straining smaller particles. Baskets are typically stainless steel for durability. You can choose the right mesh size at Cadalan to ensure efficient straining and maintain process integrity.

Dimension Chart

| Mesh Size | Microns | Inches |

|---|---|---|

| 3 | 6730 | 0.265 |

| 4 | 4760 | 0.187 |

| 5 | 4000 | 0.157 |

| 6 | 3360 | 0.132 |

| 7 | 2830 | 0.111 |

| 8 | 2380 | 0.0937 |

| 10 | 2000 | 0.0787 |

| 12 | 1680 | 0.0661 |

| 14 | 1410 | 0.0555 |

| 16 | 1190 | 0.0469 |

| 18 | 1000 | 0.0394 |

| 20 | 841 | 0.0331 |

| 25 | 707 | 0.028 |

| 30 | 595 | 0.0232 |

| 35 | 500 | 0.0197 |

| 40 | 400 | 0.0165 |

| 45 | 354 | 0.0138 |

| 50 | 297 | 0.0117 |

| 60 | 250 | 0.0098 |

| 70 | 210 | 0.0083 |

| 80 | 177 | 0.007 |

| 100 | 149 | 0.0059 |

| 120 | 125 | 0.0049 |

| 140 | 105 | 0.0041 |

| 170 | 88 | 0.0035 |

| 200 | 74 | 0.0029 |

| 230 | 63 | 0.0024 |

| 270 | 53 | 0.0021 |

| 325 | 44 | 0.0017 |

| 400 | 37 | 0.0015 |

Usages

Applications Of The Basket Strainer

Why Choose Cadalan For Basket Strainer in Singapore

Cadalan - The Best Basket Strainer Manufacturer in Singapore

Cadalan stands as a trusted leader renowned for its steadfast dedication to quality assurance, bolstered by more than a decade of industry expertise. In addition, to serving a global clientele, Cadalan delivers dependable and effective solutions tailored to various industrial needs. The company’s relentless pursuit of excellence has garnered it an esteemed reputation among customers, establishing it as the preferred provider for premium basket strainers.

Decade of Expertise

Rely on our ten years of experience in crafting dependable basket strainers that ensure the smooth operation of your systems.

Global Reach

Trusted from New York to Tokyo, our basket strainers are renowned for their quality and performance across the globe.

Quality Assurance

Our basket strainers are designed for longevity, protecting your systems against debris and further contaminants.

100+ Happy Clients

Join our roster of satisfied clients who depend on our basket strainers for the effortless maintenance of their industrial processes.

Need an industrial solution? We've got your back!

How Cadalan Produces High-Quality Basket Strainers

To produce perfect basket strainers, Cadalan undergoes a meticulous process which is mentioned below to provide better results.

Material Selection:

To produce perfect basket strainers, Cadalan undergoes a meticulous process which is mentioned below to provide better results.

Cadalan carefully selects high-quality materials, such as stainless steel or other corrosion-resistant alloys, for manufacturing basket strainers to ensure durability and performance.

Precision Engineering:

Skilled technicians at Cadalan employ precision engineering techniques to fabricate the basket strainer components, ensuring precise dimensions and optimal functionality.

Quality Control:

Cadalan implements stringent quality control procedures throughout the production process. This guarantees that every basket strainer aligns with our company’s elevated criteria for performance and dependability which is equally important.

Customization Options:

Cadalan offers customization options for basket strainers, allowing customers to tailor the design to their specific requirements, such as size, material, and filtration capacity.

Testing and Certification:

Finally, before leaving the manufacturing facility, each basket strainer undergoes thorough testing to ensure it meets industry standards and certifications for quality and performance.

How Basket Strainer Works at its Best to Remove Contaminants

As a leading basket strainer manufacturer in Singapore, Cadalan produces high-quality products that play essential roles as filters in fluid handling systems. These basket strainers efficiently eliminate undesirable particles, guaranteeing seamless and effective industrial operations.

Fluid Filtration

Basket strainers function as filters in fluid handling systems, and then remove unwanted particles and debris from the flowing liquid.

Contaminant Removal:

As the fluid passes through the strainer, the mesh or perforations in the basket trap contaminants, preventing them from entering downstream equipment.

Continuous Operation:

Basket strainers allow for continuous operation of industrial processes by maintaining the cleanliness of the fluid, thereby reducing the risk of equipment damage or failure.

Maintenance of Quality:

Moreover, basket strainers contribute to maintaining the quality and integrity of the end product or process by ensuring the fluid remains free from contaminants.

Process Efficiency:

The effective functioning of basket strainers leads to improved process efficiency and reliability, as they help prevent clogging and blockages that can disrupt operations.

We Work Globally

Our Clients

With a strong focus on durability, efficiency, and customer satisfaction,

we pride ourselves on delivering reliable filtration solutions trusted by clients across the globe.

___Testimonials

The Best Industry

The Best Industry

The Best Industry

Connect

Get Into Touch

Your Questions

Frequently Asked Questions

The cleaning procedure for a Basket Strainer involves isolating the system, removing the basket for thorough cleaning, inspecting and replacing seals as needed, and reassembling the strainer before reconnecting it to the system. Regular maintenance ensures optimal performance and longevity.

Basket strainers find widespread applications across industries, from petrochemicals and water treatment to pharmaceuticals, serving as crucial components for filtering out contaminants and protecting downstream equipment, ensuring smooth and efficient operations.

Select the right basket strainer by considering factors such as flow rate compatibility, particle size requirements, material compatibility with the fluid, and adherence to industry standards, ensuring optimal performance tailored to your specific fluid handling needs.

A typical maintenance schedule for a basket strainer involves regular inspections and cleaning, typically quarterly or semi-annually, depending on usage. Cleaning is generally straightforward, with easy basket removal and simple procedures, contributing to minimal downtime and efficient maintenance.

The pressure drop in a basket strainer is crucial for assessing system efficiency; minimizing it is essential for optimal performance. Proper sizing, selecting the right mesh size, and ensuring regular cleaning are key strategies to minimize pressure drop and maintain the strainer’s effectiveness in fluid systems.

Basket strainers come in various standard sizes, but many manufacturers offer customization options to tailor the dimensions and configurations based on specific fluid system requirements, ensuring a precise fit for diverse applications.

The sealing mechanism in a basket strainer is crucial for preventing the bypass of contaminants, ensuring efficient filtration. It maintains a secure seal, directing the fluid through the basket, enhancing the strainer’s effectiveness in removing particles and protecting downstream equipment.

Absolutely, at Cadalan, we specialize in crafting custom designs to suit specific industrial applications. Our experienced team collaborates closely with clients, ensuring tailored solutions that meet exact requirements for materials, sizes, and specialized features.

Cadalan leads as Singapore’s premier basket strainer manufacturer due to our unwavering commitment to quality, extensive industry experience, customer-centric approach, and proven track record of delivering reliable solutions for diverse industrial needs.