Experience Efficient Filtration & Functionality With Our Premier Y Strainers

High-quality Y strainer supplier in UAE for diverse industrial applications

About Us

We Are a Leading Y Strainer supplier in the UAE

At Cadalan, we have a decade of experience in manufacturing and supplying high-quality strainers. Our focus is on precision, innovation, and ensuring customer satisfaction makes us the leading Y strainer supplier in UAE. The exceptional craftsmanship of our wide range of strainers, designed for industries like manufacturing, processing plants, refineries, and oil and gas companies, demonstrates our commitment to excellence. We place importance on technological innovation and sustainable practices, continually pushing boundaries to establish new benchmarks in durability and performance. We are trusted worldwide because we focus on quality and customers. Our products are used in many countries, including the USA, UK, Australia, Saudi Arabia, Qatar, UAE, Africa, Thailand, Vietnam, New Zealand, Oman, and Indonesia.

Product Specifications

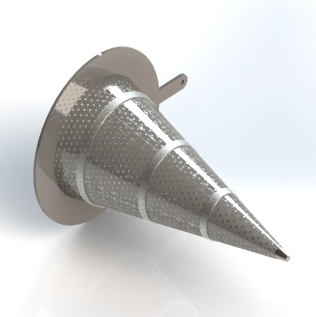

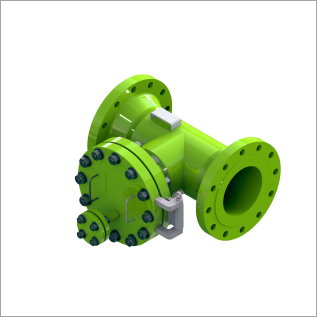

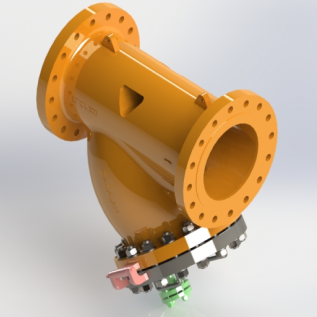

Y Strainer

The Y strainer is crucial in fluid systems because of its unique Y-shaped design, which effectively filters out impurities and debris. Our Y strainers at Cadalan are manufactured with precision to meet high-quality standards. We offer duplex basket strainers in sizes up to 24 inches and classes from #150 to #10,000.

Cadalan marks it as a high-quality Y strainer supplier in UAE with careful material selection, and precision engineering, with exceptional efficiency. Each component undergoes thorough testing and inspection to ensure durability and efficiency. We select materials for their resilience and compatibility with various fluids, making our Y strainers a reliable choice for many applications.

- Sizes - 1 to 24 inches

- Types: Casting, Fabricated & Butt Welded

- Connection: Flanged & Butt Welded

- Classes : #150, #300, #400, #600, #900, #1500, #2500 upto #10,000

Fabricated Type Y Strainer

- Carbon Steel -ASTM A106 GR B/C, API 5L X65, A333 GR 6, ASTM A671

- Stainless Steel - ASTM A312 TP316 / 316L, ASTM A358 TP316 / 316L

- Duplex Stainless Steel - ASTM A928 S31803, ASTM A790 S31800

- Super Duplex Stainless Steel - ASTM A928 S32750 / 32760, ASTM A790 S32750/32760

- Nickel Aluminium Bronze Alloy - ASTM B148 C95800

- Monel -ASTM B165 K400/K500 (UNS N05400 / UNSN04400)

- Titanium grade 2 & 5 - ASTM B337 GR2 / GR5

Casting Type Y Strainer

- Carbon Steel - A216 WCB / WCC

- Low-Temperature Carbon Steel - LF2

- Stainless Steel - CF8 | CF8M | CF3 | CF3M

- Duplex Stainless Steel -A995 GR.4A

- Super Duplex Stainless Steel - A995 GR.5A

- Nickel Aluminium Bronze Alloy - ASTM B148 C95800

- Monel - K400 / K500

- Materials comply with NACE MR 01-75 NORSOK requirements

Dimension Chart for Y Strainer in Detail

Discover the specifications of our Y strainers below for accurate sizing information.

| SIZE | DIMENSIONS | WEIGHTS | |||||||||||||||||||

| A (END TO END) | B (HORIZONTAL) | C (VERTICAL) | D (FILTER REMOVAL) | ||||||||||||||||||

| CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | ||||||||||||

| INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | LBS | KGS | LBS | KGS |

| 2 | 50 | 10.43 | 265 | 10.55 | 268 | 5.04 | 128 | 5.04 | 128 | 5.94 | 151 | 6.30 | 160 | 10.83 | 275 | 11.81 | 300 | 30.86468 | 14 | 44.09 | 20 |

| 3 | 80 | 12.28 | 312 | 13.07 | 332 | 6.77 | 172 | 6.77 | 172 | 7.20 | 183 | 7.20 | 183 | 13.39 | 340 | 14.17 | 360 | 57.32012 | 26 | 79.37 | 36 |

| 4 | 100 | 14.33 | 364 | 15.04 | 382 | 8.27 | 210 | 8.27 | 210 | 8.23 | 209 | 8.90 | 226 | 16.14 | 410 | 16.34 | 415 | 83.77556 | 38 | 127.87 | 58 |

| 6 | 150 | 18.27 | 464 | 19.06 | 484 | 11.26 | 286 | 11.26 | 286 | 10.28 | 261 | 11.10 | 282 | 20.47 | 520 | 20.47 | 520 | 141.09568 | 64 | 249.12 | 113 |

| 8 | 200 | 22.05 | 560 | 22.76 | 578 | 14.02 | 356 | 14.02 | 356 | 12.28 | 312 | 13.19 | 335 | 24.41 | 620 | 25.00 | 635 | 231.4851 | 105 | 379.19 | 172 |

| 10 | 250 | 25.04 | 636 | 26.30 | 668 | 17.01 | 432 | 17.01 | 432 | 13.86 | 352 | 15.16 | 385 | 28.35 | 720 | 29.13 | 740 | 330.693 | 150 | 597.45 | 271 |

| 12 | 300 | 29.06 | 738 | 30.31 | 770 | 20.00 | 508 | 20.00 | 508 | 15.91 | 404 | 18.43 | 468 | 32.68 | 830 | 32.28 | 820 | 493.83488 | 224 | 873.03 | 396 |

| 14 | 350 | 31.97 | 812 | 33.23 | 844 | 21.97 | 558 | 21.97 | 558 | 17.48 | 444 | 18.86 | 479 | 35.83 | 910 | 32.68 | 830 | 650.3629 | 295 | 1179.47 | 535 |

| 16 | 400 | 34.02 | 864 | 35.51 | 902 | 24.02 | 610 | 24.02 | 610 | 18.58 | 472 | 20.16 | 512 | 38.58 | 980 | 38.98 | 990 | 837.7556 | 380 | 1521.19 | 690 |

| 18 | 450 | 38.03 | 966 | 39.53 | 1004 | 27.01 | 686 | 27.01 | 686 | 20.71 | 526 | 22.24 | 565 | 43.31 | 1100 | 43.90 | 1115 | 1042.78526 | 473 | 1940.07 | 880 |

| 20 | 500 | 41.42 | 1052 | 42.76 | 1086 | 30.00 | 762 | 30.00 | 762 | 22.52 | 572 | 24.02 | 610 | 47.24 | 1200 | 47.64 | 1210 | 1327.18124 | 602 | 2425.08 | 1100 |

| 24 | 600 | 46.06 | 1170 | 47.32 | 1202 | 34.02 | 864 | 34.02 | 864 | 25.04 | 636 | 26.54 | 674 | 53.82 | 1367 | 51.57 | 1310 | 1924.63326 | 873 | 3644.24 | 1653 |

Sizing the mesh filter for a Y strainer

Understanding the mesh size and micron rating is crucial for the efficiency of a Y strainer’s filtration. The mesh size refers to the number of openings per inch in the strainer screen, while the micron rating indicates the size of particles the strainer can trap effectively.

A Y strainer with a lower mesh size has larger openings, making it suitable for capturing bigger particles. On the other hand, a higher mesh size means smaller openings, which are better for finer filtration. The micron size specifies the diameter of particles that the strainer can filter, with smaller micron sizes indicating better filtration for finer particles.

By selecting the mesh and micron sizes carefully based on the application’s needs, Y strainers can remove impurities from fluid streams effectively, ensuring the process’s integrity and quality. As a prominent Y strainer supplier in UAE, Cadalan enables you to achieve optimal filtration efficiency.

What is Mesh Size:

- Unit of Measurement:Mesh size is commonly denoted by the number of openings per linear inch.

- Definition: Mesh size signifies the quantity of openings per linear inch in a strainer or filter, frequently applied in woven wire mesh or perforated plate filters.

What is Micron Size:

- Unit of Measurement: The micron (µm) is a metric length unit equivalent to one-millionth of a meter.

- Definition: Micron size denotes the diameter of a particle capable of passing through an opening in a strainer or filter.

Dimension Chart

| Mesh Size | Microns | Inches |

|---|---|---|

| 3 | 6730 | 0.265 |

| 4 | 4760 | 0.187 |

| 5 | 4000 | 0.157 |

| 6 | 3360 | 0.132 |

| 7 | 2830 | 0.111 |

| 8 | 2380 | 0.0937 |

| 10 | 2000 | 0.0787 |

| 12 | 1680 | 0.0661 |

| 14 | 1410 | 0.0555 |

| 16 | 1190 | 0.0469 |

| 18 | 1000 | 0.0394 |

| 20 | 841 | 0.0331 |

| 25 | 707 | 0.028 |

| 30 | 595 | 0.0232 |

| 35 | 500 | 0.0197 |

| 40 | 400 | 0.0165 |

| 45 | 354 | 0.0138 |

| 50 | 297 | 0.0117 |

| 60 | 250 | 0.0098 |

| 70 | 210 | 0.0083 |

| 80 | 177 | 0.007 |

| 100 | 149 | 0.0059 |

| 120 | 125 | 0.0049 |

| 140 | 105 | 0.0041 |

| 170 | 88 | 0.0035 |

| 200 | 74 | 0.0029 |

| 230 | 63 | 0.0024 |

| 270 | 53 | 0.0021 |

| 325 | 44 | 0.0017 |

| 400 | 37 | 0.0015 |

Usages

Applications Of The Y Strainerr

Why Choose

Why Choose Cadalan For Y Strainer Supplier in UAE

From the viewpoint of the Y strainer manufacturing sector, Cadalan stands out as a reputable leading Y strainer supplier in UAE. We are known for our great commitment to uphold the highest quality benchmarks, backed by over ten years of specialized industry knowledge. With a broad global footprint, we cater to a diverse international customer base by delivering dependable and customized solutions that address a range of industrial needs. Through our unwavering pursuit of perfection, we have cultivated a strong relationship with customers, establishing us as the premier option for individuals in search of premium Y strainers.

Decade of Expertise

Trust our decade-long expertise in designing reliable basket strainers that keep your systems running smoothly.

Global Reach

From New York to Tokyo, our Y strainers are trusted worldwide for their quality and performance.

Quality Assurance

Our Y strainers are built to last, ensuring your systems are protected from debris and contaminants.

100+ Happy Clients

Join our satisfied clients who rely on our Y strainers to maintain their industrial processes with ease.

Need an industrial solution? We've got your back!

Features And Benefits Of Y Strainer

The future of Y Strainers looks bright, with exciting advancements on the horizon that will benefit fluid systems in many industries:

Better Filtration:

New Y Strainer designs will be more efficient at filtering out even tiny particles. This will keep pipelines cleaner and protect equipment downstream, making fluid systems work better overall.

Smart Features:

Y Strainers of the future might be able to connect to sensors and technology. This could let them be monitored in real-time, so potential issues can be spotted early and fixed before they become big problems.

Stronger Materials:

Scientists are working on using stronger materials for Y Strainers. This could make them last longer, resist corrosion better, and handle tough conditions without breaking.

Eco-Friendly:

Future Y Strainers might use materials and processes that are better for the environment. This is important as more industries focus on sustainability and protecting the planet.

Cost-Effective:

Improvements in Y Strainer technology could save money. By filtering more efficiently, they can prevent damage to equipment downstream, cutting down on maintenance costs and downtime. Plus, new manufacturing methods could make them cheaper to produce.

Overall, these advancements in Y Strainers promise a future where fluid systems are more reliable, cost-effective, and environmentally friendly across various industries.

How Efficiently Cadalan’s Y Strainer Filter the Fluids

Y strainers are essential components in fluid filtration for industrial applications. Their innovative design effectively removes impurities, ensuring the smooth operation of machinery. Offering customizable options and easy maintenance. They also provide a cost-effective solution for industries globally. Experience the efficiency and dependability of Y strainers in fluid filtration processes.

Ensuring Clean Fluids:

In the world of manufacturing, the efficiency of machinery hinges on the cleanliness of the fluids flowing through them. Y strainers play a pivotal role in this process, acting as the first line of defense against impurities. Their unique Y-shaped design allows them to filter out solid particles and debris, ensuring that only clean fluid passes through.

Tailored Solutions:

One of the key strengths of Y strainers is their versatility. Manufacturers offer a wide range of options, including different mesh sizes and materials, to suit the specific needs of various industries. This customization ensures that Y strainers can effectively filter out particles of different sizes, providing tailored solutions for different applications.

Simplicity in Maintenance:

Despite their complex role, Y strainers are surprisingly easy to maintain. Many models come with removable strainer elements that can be easily cleaned or replaced when necessary. This simplicity in maintenance ensures that downtime is minimized, and operations can continue smoothly.

Built to Last:

Y strainers are built to withstand the rigors of industrial environments. Constructed from durable materials such as stainless steel or carbon steel, they are resistant to corrosion and designed to last for years. This durability ensures that they can continue to provide reliable filtration for extended periods.

Cost-Effective Filtration:

In addition to their efficiency and durability, Y strainers are also cost-effective. They provide efficient filtration without the need for frequent replacement or maintenance, helping industries save on operational costs in the long run.

Y strainers are a critical component in ensuring the efficiency and longevity of industrial machinery. Their ability to efficiently filter out impurities, coupled with their versatility, ease of maintenance, durability, and cost-effectiveness, make them an indispensable tool in various industries where clean fluids are essential.

We Work Globally

Our Clients

With a strong focus on durability, efficiency, and customer satisfaction,

we pride ourselves on delivering reliable filtration solutions trusted by clients across the globe.

___Testimonials

The Best Industry

The Best Industry

The Best Industry

Connect

Get Into Touch

Your Questions

Frequently Asked Questions

Cleaning a Y Strainer involves isolating and depressurizing the system, removing the cap to access the strainer element, inspecting for debris, and cleaning or replacing the element as necessary. Check seals and housing for wear, reassemble the strainer, and reconnect it to the system. Regular maintenance is crucial for optimal performance and preventing potential issues in fluid filtration.

Y Strainers are widely used in various industries for efficient fluid filtration. They are essential in applications such as chemical processing, water treatment, oil and gas, and manufacturing. In these sectors, Y Strainers effectively remove impurities, protecting equipment and ensuring the smooth flow of fluids. Their versatility and reliability make them essential components in diverse industrial processes.

Y Strainers typically require maintenance every 3 to 6 months, depending on the specific application and fluid conditions. Cleaning is simple: isolate the strainer, remove the cover, inspect and clean the mesh or replace it if necessary, and reassemble. Regular maintenance ensures optimal performance and extends the life of the Y Strainer in fluid systems.

Pressure drop in a Y Strainer affects system efficiency. To minimize pressure drop, choose a Y Strainer with a large area and suitable mesh size. Regularly clean or replace the element to maintain unobstructed fluid flow. Proper sizing, installation, and maintenance are critical for reducing pressure drop and maximizing system efficiency.

Y Strainers come in standard sizes but can be customized to meet specific requirements. This flexibility ensures suitability for diverse applications. Consult manufacturers for insights into the best sizing options based on specific fluid handling needs.

The sealing mechanism in a Y Strainer is essential for maintaining a tight seal, preventing unfiltered fluid bypass, and optimizing filtration efficiency. A well-designed mechanism ensures effective impurity capture, safeguarding downstream equipment and maintaining fluid system integrity. Regular inspection and maintenance are crucial for sustained, efficient filtration performance.

Yes, we specialize in tailored solutions and offer custom designs for diverse industrial applications. Our expertise ensures precise adaptations to meet unique requirements, promoting optimal performance. Collaborating closely with clients, we create bespoke solutions that underscore our commitment to precision and versatility. Trust us for customized designs that enhance efficiency and reliability in your industrial processes.