Precision Manufacturing for Uncompromising Quality

Enhance Your Filtration Efficiency with Our Top-Grade Conical Strainers

About Us

Premier Conical Strainer Manufacturer in Singapore

Cadalan, a leading conical strainer manufacturer in Singapore, with 10+ years of excellence, is dedicated to supplying components with precision, innovation, and customer satisfaction. We take pride in the top-notch craftsmanship of our wide range of strainers, tailored for industries such as the manufacturing and processing chemical industry, power generation, automotive industry, and pulp and paper industry. At Cadalan, our passion for innovation and sustainability propels us forward, continuously redefining the boundaries of durability and performance. We stand firm in our dedication to quality and prioritize our customers in every aspect of our work, earning us trust and recognition worldwide. Our Product presence extends globally with a strong presence in the USA, UK, Australia, Saudi Arabia, Qatar, UAE, Africa, Thailand, Vietnam, New Zealand, Oman, and Indonesia.

Product Specifications

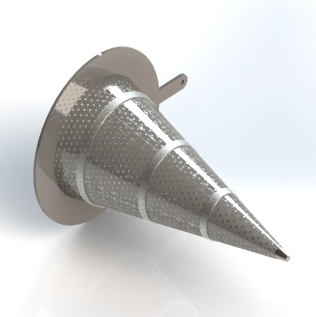

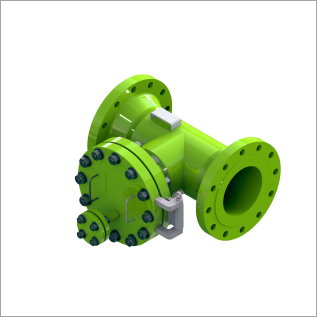

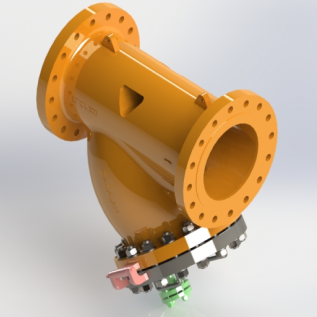

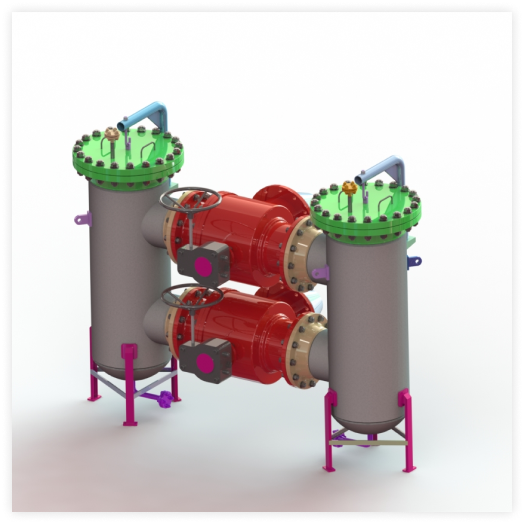

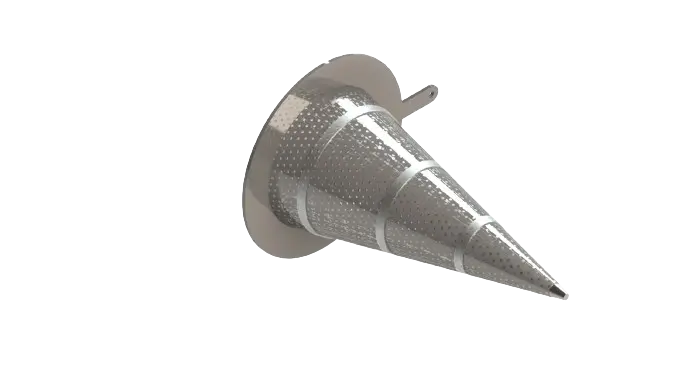

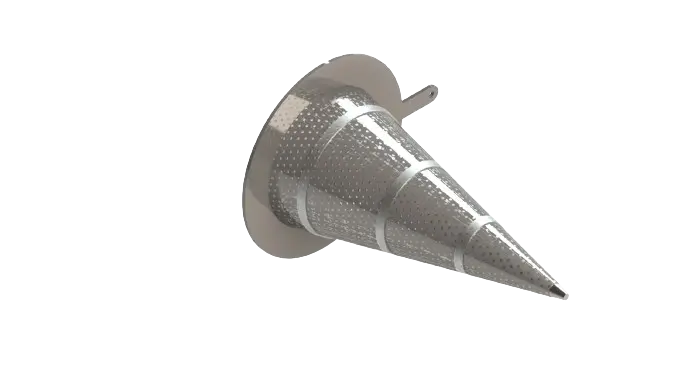

Conical Strainer

Conical Strainer stands as a crucial filtration solution for pipelines, guarding against impurities in the liquid flow. They are usually positioned horizontally within piping systems to prevent damage, and shield gauges, pumps, and valves from harm’s reach. These strainers are cost-effective and are deployed mostly before the start of plant operations. With their mesh, they effectively catch particles, keeping the liquid clean and pure. At Cadalan, our conical strainers are offered in sizes up to 24 inches and classes ranging from #150 to #10,000, providing a comprehensive range to meet various requirements.

At Cadalan, we’re dedicated to quality. Our strict quality control ensures our conical strainers are always top-notch in durability and effectiveness. This commitment sets Cadalan as the leading conical strainer manufacturer in Singapore.

- Sizes - 1 to 24 inches

- Types: Casting, Fabricated & Butt Welded

- Connection: Flanged & Butt Welded

- Classes : #150, #300, #400, #600, #900, #1500, #2500 upto #10,000

Fabricated Type Conical Strainer

- Carbon Steel - ASTM A106 GR B/C, API 5L X65, A333 GR 6, ASTM A671

- Stainless Steel - ASTM A312 TP316 / 316L, ASTM A358 TP316 / 316L

- Duplex Stainless Steel - ASTM A928 S31803, ASTM A790 S31800

- Super Duplex Stainless Steel - ASTM A928 S32750 / 32760, ASTM A790 S32750/32760

- Nickel Aluminium Bronze Alloy - ASTM B148 C95800

- Monel - ASTM B165 K400/K500 (UNS N05400 / UNSN04400)

- Titanium grade 2 & 5 - ASTM B337 GR2 / GR5

Casting Type Conical Strainer

- Carbon Steel - A216 WCB / WCC

- Low - LF2

- Stainless Steel - CF8 | CF8M | CF3 | CF3M

- Duplex Stainless Steel - A995 GR.5A

- Super Duplex Stainless Steel - A995 GR.5A

- Nickel Aluminium Bronze Alloy - ASTM B148 C95800

- Monel - K400 / K500

- Titanium Grade 2 & 5 - ASTM B337 GR 2 / GR 5

- Materials comply with NACE MR 01-75 NORSOK requirements

Our Dimension Chart of Conical Strainer in Detail

Ensure precision with your selection by reviewing the dimensions of our conical strainers below

| SIZE | DIMENSIONS | WEIGHTS | |||||||||||||||||||

| A (END TO END) | B (HORIZONTAL) | C (VERTICAL) | D (FILTER REMOVAL) | ||||||||||||||||||

| CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | CLASS 150 | CLASS 300 | ||||||||||||

| INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | INCH | MM | LBS | KGS | LBS | KGS |

| 2 | 50 | 10.43 | 265 | 10.55 | 268 | 5.04 | 128 | 5.04 | 128 | 5.94 | 151 | 6.30 | 160 | 10.83 | 275 | 11.81 | 300 | 30.86468 | 14 | 44.09 | 20 |

| 3 | 80 | 12.28 | 312 | 13.07 | 332 | 6.77 | 172 | 6.77 | 172 | 7.20 | 183 | 7.20 | 183 | 13.39 | 340 | 14.17 | 360 | 57.32012 | 26 | 79.37 | 36 |

| 4 | 100 | 14.33 | 364 | 15.04 | 382 | 8.27 | 210 | 8.27 | 210 | 8.23 | 209 | 8.90 | 226 | 16.14 | 410 | 16.34 | 415 | 83.77556 | 38 | 127.87 | 58 |

| 6 | 150 | 18.27 | 464 | 19.06 | 484 | 11.26 | 286 | 11.26 | 286 | 10.28 | 261 | 11.10 | 282 | 20.47 | 520 | 20.47 | 520 | 141.09568 | 64 | 249.12 | 113 |

| 8 | 200 | 22.05 | 560 | 22.76 | 578 | 14.02 | 356 | 14.02 | 356 | 12.28 | 312 | 13.19 | 335 | 24.41 | 620 | 25.00 | 635 | 231.4851 | 105 | 379.19 | 172 |

| 10 | 250 | 25.04 | 636 | 26.30 | 668 | 17.01 | 432 | 17.01 | 432 | 13.86 | 352 | 15.16 | 385 | 28.35 | 720 | 29.13 | 740 | 330.693 | 150 | 597.45 | 271 |

| 12 | 300 | 29.06 | 738 | 30.31 | 770 | 20.00 | 508 | 20.00 | 508 | 15.91 | 404 | 18.43 | 468 | 32.68 | 830 | 32.28 | 820 | 493.83488 | 224 | 873.03 | 396 |

| 14 | 350 | 31.97 | 812 | 33.23 | 844 | 21.97 | 558 | 21.97 | 558 | 17.48 | 444 | 18.86 | 479 | 35.83 | 910 | 32.68 | 830 | 650.3629 | 295 | 1179.47 | 535 |

| 16 | 400 | 34.02 | 864 | 35.51 | 902 | 24.02 | 610 | 24.02 | 610 | 18.58 | 472 | 20.16 | 512 | 38.58 | 980 | 38.98 | 990 | 837.7556 | 380 | 1521.19 | 690 |

| 18 | 450 | 38.03 | 966 | 39.53 | 1004 | 27.01 | 686 | 27.01 | 686 | 20.71 | 526 | 22.24 | 565 | 43.31 | 1100 | 43.90 | 1115 | 1042.78526 | 473 | 1940.07 | 880 |

| 20 | 500 | 41.42 | 1052 | 42.76 | 1086 | 30.00 | 762 | 30.00 | 762 | 22.52 | 572 | 24.02 | 610 | 47.24 | 1200 | 47.64 | 1210 | 1327.18124 | 602 | 2425.08 | 1100 |

| 24 | 600 | 46.06 | 1170 | 47.32 | 1202 | 34.02 | 864 | 34.02 | 864 | 25.04 | 636 | 26.54 | 674 | 53.82 | 1367 | 51.57 | 1310 | 1924.63326 | 873 | 3644.24 | 1653 |

Sizing the mesh filter for a Conical strainer

The effectiveness of filtration in a conical strainer depends a lot on the size of its mesh and micron. Mesh size indicates the number of openings per inch in the strainer screen, while micron size refers to the particle size the strainer can capture.

A lower mesh size means larger openings, suitable for capturing bigger particles, whereas a higher mesh size implies smaller openings, ideal for finer filtration. The micron size specifies the diameter of particles that the strainer can filter out, with smaller micron sizes indicating better filtration capabilities.

Choosing the right mesh and micron dimensions tailored to the specific application requirements ensures that conical strainers can efficiently remove contaminants from fluid streams, maintaining the integrity and quality of the process.

Dimension Chart

| Mesh Size | Microns | Inches |

|---|---|---|

| 3 | 6730 | 0.265 |

| 4 | 4760 | 0.187 |

| 5 | 4000 | 0.157 |

| 6 | 3360 | 0.132 |

| 7 | 2830 | 0.111 |

| 8 | 2380 | 0.0937 |

| 10 | 2000 | 0.0787 |

| 12 | 1680 | 0.0661 |

| 14 | 1410 | 0.0555 |

| 16 | 1190 | 0.0469 |

| 18 | 1000 | 0.0394 |

| 20 | 841 | 0.0331 |

| 25 | 707 | 0.028 |

| 30 | 595 | 0.0232 |

| 35 | 500 | 0.0197 |

| 40 | 400 | 0.0165 |

| 45 | 354 | 0.0138 |

| 50 | 297 | 0.0117 |

| 60 | 250 | 0.0098 |

| 70 | 210 | 0.0083 |

| 80 | 177 | 0.007 |

| 100 | 149 | 0.0059 |

| 120 | 125 | 0.0049 |

| 140 | 105 | 0.0041 |

| 170 | 88 | 0.0035 |

| 200 | 74 | 0.0029 |

| 230 | 63 | 0.0024 |

| 270 | 53 | 0.0021 |

| 325 | 44 | 0.0017 |

| 400 | 37 | 0.0015 |

Usages

Applications Of The Conical Strainer

Why Choose Cadalan For Conical Strainer in Singapore

Cadalan - The Best Conical Strainer Manufacturer in Singapore

Cadalan is a reputable leader in conical strainer manufacturing, recognized for its steadfast dedication to quality assurance and backed by over a decade of industry expertise. With a global footprint, Cadalan caters to clients worldwide, delivering dependable and effective solutions for a wide range of industrial needs. The company’s unwavering commitment to excellence has garnered a strong reputation among clients, establishing it as the preferred choice for those seeking top-quality conical strainers.

Decade of Expertise

Rely on our ten years of experience in crafting dependable basket strainers that ensure the smooth operation of your systems.

Global Reach

Trusted from New York to Tokyo, our basket strainers are renowned for their quality and performance across the globe.

Assured Durability:

Our basket strainers are designed for longevity, protecting your systems against debris and contaminants.

100+ Satisfied Customers:

Join our roster of satisfied clients who depend on our basket strainers for the effortless maintenance of their industrial processes.

Need an industrial solution? We've got your back!

Benefits of Conical Strainers in Industrial Applications

The following benefits make conical strainers an essential component in many industrial processes where efficient filtration is crucial.

Efficient Filtration:

Conical strainers effectively trap solid particles and debris from fluid streams, protecting downstream equipment.

Low-Pressure Drop:

They offer minimal impact on fluid flow rates due to their low-pressure drop, ensuring efficient operation.

Easy Maintenance:

Conical strainers are easy to install and maintain, reducing downtime for cleaning or replacement.

Versatility:

They can be used in various industries and applications, adapting to different fluid types and operating conditions.

Cost-Effective:

Conical strainers provide reliable performance at a reasonable cost, making them a cost-effective filtration solution.

How Conical Strainer Works at its Best to Remove Contaminants

As a prominent top-tier conical strainer manufacturer in Singapore, Cadalan’s products are pivotal in fluid handling systems, ensuring the seamless and effective functioning of industrial operations through efficient particle filtration.

Fluid Filtration

Integral to fluid handling systems, conical strainers effectively eliminate unwanted particles and debris from fluid streams, preserving the overall integrity of industrial processes.

Contaminant Removal:

Engineered for optimal performance, conical strainers adeptly capture contaminants during fluid passage, safeguarding downstream equipment from potential harm.

Continuous Operation:

Conical strainers facilitate uninterrupted industrial processes by upholding fluid cleanliness, mitigating the risk of equipment breakdowns and operational halts.

Quality Preservation

By upholding fluid purity, conical strainers play a crucial role in maintaining the high quality and integrity of final products or processes.

Enhanced Efficiency:

Through their dependable performance, conical strainers bolster process efficiency and reliability, averting obstructions and blockages that could disrupt operations, thus ensuring seamless and consistent processes.

We Work Globally

Our Clients

With a strong focus on durability, efficiency, and customer satisfaction,

we pride ourselves on delivering reliable filtration solutions trusted by clients across the globe.

___Testimonials

The Best Industry

The Best Industry

The Best Industry

Connect

Get Into Touch

Your Questions

Frequently Asked Questions

The cleaning procedure for a Conical Strainer involves isolating the system, removing the conical element for thorough cleaning, inspecting and replacing seals as needed, and reassembling the strainer before reconnecting it to the system. Regular maintenance ensures optimal performance and longevity.

Conical strainers find widespread applications across industries, from petrochemicals and water treatment to pharmaceuticals, serving as crucial components for filtering out contaminants and protecting downstream equipment, ensuring smooth and efficient operations.

Select the right conical strainer by considering factors such as flow rate compatibility, particle size requirements, material compatibility with the fluid, and adherence to industry standards, ensuring optimal performance tailored to your specific fluid handling needs.

A typical maintenance schedule for a conical strainer involves regular inspections and cleaning, typically quarterly or semi-annually, depending on usage. Cleaning is generally straightforward, with easy conical element removal and simple procedures, contributing to minimal downtime and efficient maintenance.

The pressure drop in a conical strainer is crucial for assessing system efficiency; minimizing it is essential for optimal performance. Proper sizing, selecting the right mesh size, and ensuring regular cleaning are key strategies to minimize pressure drop and maintain the strainer’s effectiveness in fluid systems.

Conical strainers come in various standard sizes, but many manufacturers offer customization options to tailor the dimensions and configurations based on specific fluid system requirements, ensuring a precise fit for diverse applications.

The sealing mechanism in a conical strainer is crucial for preventing the bypass of contaminants to ensure efficient filtration. It maintains a secure seal, directing the fluid through the conical element, enhancing the strainer’s effectiveness in removing particles and protecting downstream equipment.

Absolutely, at Cadalan, we specialize in crafting custom designs to suit specific industrial applications. Our experienced team collaborates closely with clients, ensuring tailored solutions that meet exact requirements for materials, sizes, and specialized features.